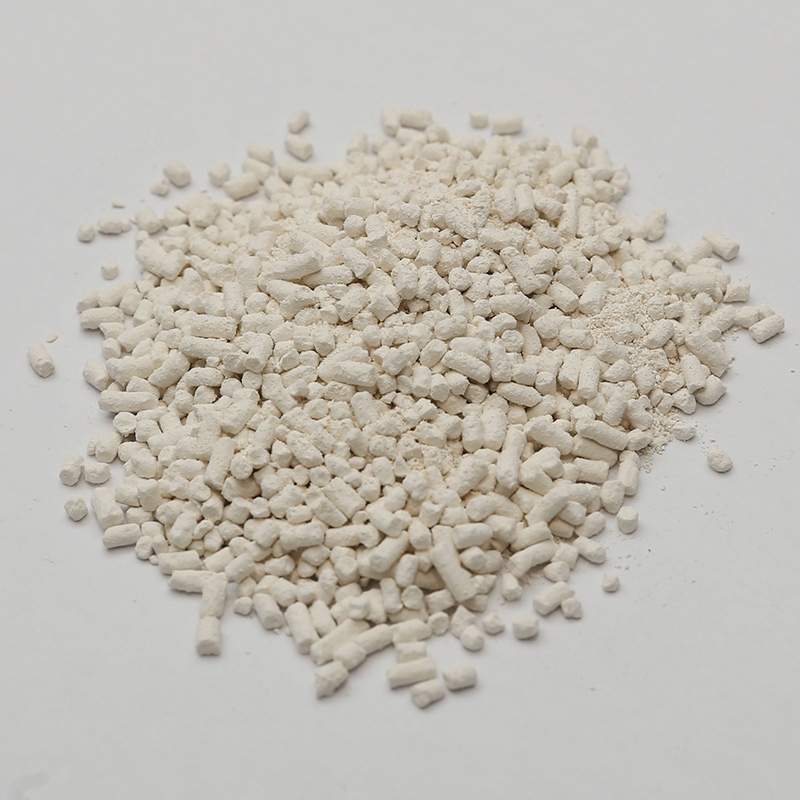

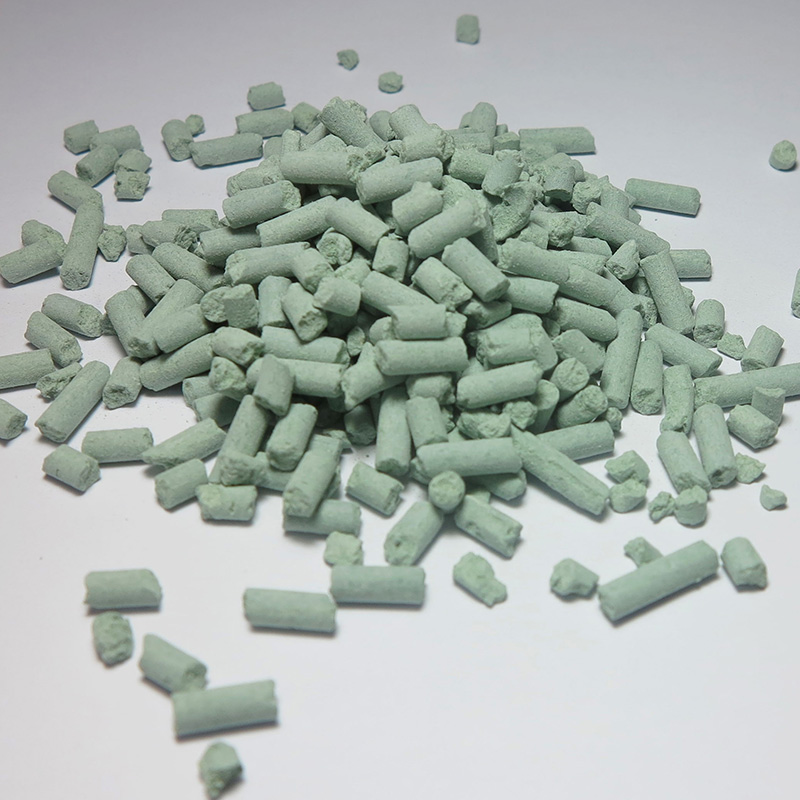

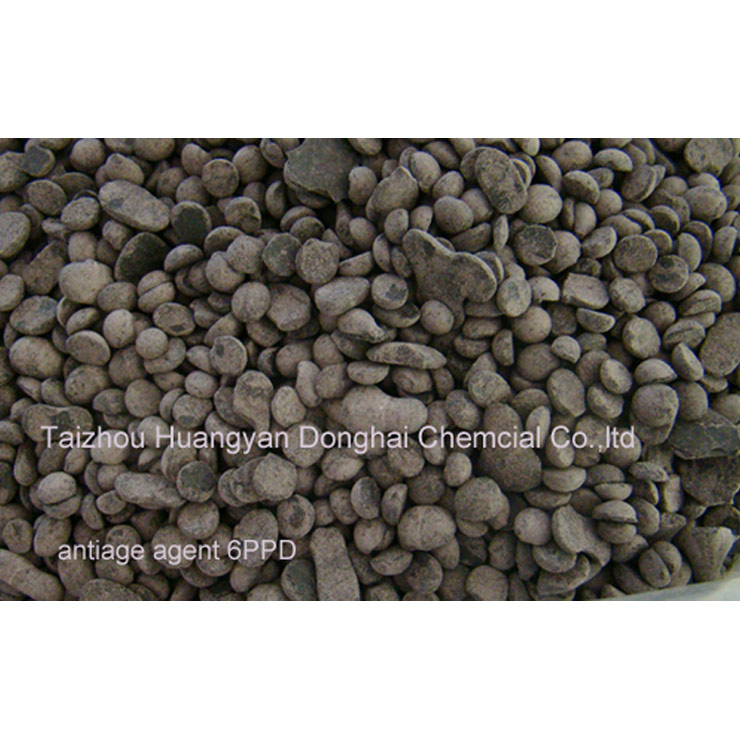

Sale OEM Peptizing Liquid Rubber Agent Additives in China

Rubber and polymers are essential materials in various industrial applications due to their versatility, durability, and flexibility. The processing of rubber and polymer compounds, however, can be challenging due to their high molecular weight and the need for effective manipulation during manufacturing. This is where peptizing agents come into play. They are substances that help break down the high molecular weight of polymers, facilitating better processing and improving the final product’s properties. The role of peptizing agents in rubber and polymer processing has gained significant attention over the years, and their use has expanded across many industries.

A Sale peptizing agent functions primarily by promoting the depolymerization of rubber or polymers, thereby reducing their viscosity. This allows the material to be more easily handled and processed during the various stages of manufacturing. They are particularly important in the production of natural rubber, where the raw material often exists in a solid, highly viscous state.

In the rubber industry, the use of peptizing agents is especially critical in the initial stages of processing, where the rubber is often in its raw form, unrefined, and tough to manipulate. Natural rubber, for instance, is harvested in a form that is not easily processed, and thus, they help break down the rubber into a more workable state. Without these agents, the rubber would be difficult to mold into the desired shapes or forms. Additionally, they help improve the distribution of additives like fillers, plasticizers, and curing agents, all of which are crucial to the final properties of the rubber.

In polymer processing, they have a similar role. Polymers are long chains of molecules that often exhibit high viscosity and limited processability in their raw state. When dealing with thermoplastic or thermoset polymers, the use of peptizing agents can promote better flow properties, which are essential for extrusion, injection molding, and other polymer processing techniques. The reduced viscosity due to peptization results in improved processing efficiency and ensures that the polymers are more uniform and free of defects.

The effectiveness of OEM Liquid Rubber Additives can depend on several factors, including the type of rubber or polymer being processed, the nature of the peptizing agent itself, and the processing conditions. For instance, different types of natural rubber or synthetic polymers may require different ones. Some agents may work better with particular materials, while others may be more universal in their application. The concentration of it is also an important consideration. Too much of an agent can result in over-peptization, which may compromise the strength and elasticity of the material. On the other hand, too little of an agent may result in incomplete processing and inefficient production.

In addition to improving the ease of processing, peptizing agents can also influence the final mechanical properties of rubber and polymers. In rubber production, the balance between the rubber’s viscosity and its elasticity is crucial for determining the final product's performance characteristics. they help strike this balance by facilitating the dispersion of curing agents and other additives, ensuring that the rubber achieves the desired hardness, elasticity, and durability. For polymers, it can help achieve consistent molecular weight distribution, which contributes to better mechanical properties such as tensile strength, impact resistance, and flexibility.

In summary, Rubber Additives in China play a crucial role in both rubber and polymer processing by facilitating the reduction of viscosity and improving processability. They are instrumental in making raw materials more workable and in ensuring the proper distribution of additives and fillers, which are key to achieving the desired material properties. Whether in the production of natural rubber, synthetic rubber, or polymers, peptizing agents help to optimize processing efficiency, improve the final product's mechanical properties, and contribute to sustainable manufacturing practices. As the demand for high-performance materials continues to grow, the role of peptizing agents in rubber and polymer processing is likely to become even more significant in the future.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体