In the world of rubber manufacturing, creating a durable and reliable product requires more than just selecting the right base material. One crucial element that often determines the lifespan and performance of rubber components is the choice of a rubber antioxidant agent. This additive helps protect rubber from degradation caused by exposure to oxygen, heat, and ozone.

The step to optimizing rubber formulations is understanding the specific conditions the rubber product will face during its use. Different applications, whether automotive hoses, seals, or footwear soles, expose rubber to varying levels of heat, mechanical stress, and environmental factors. A rubber antioxidant agent that works well in one application may not be ideal for another. Manufacturers should assess these conditions carefully to select an antioxidant agent that offers the many appropriate protection.

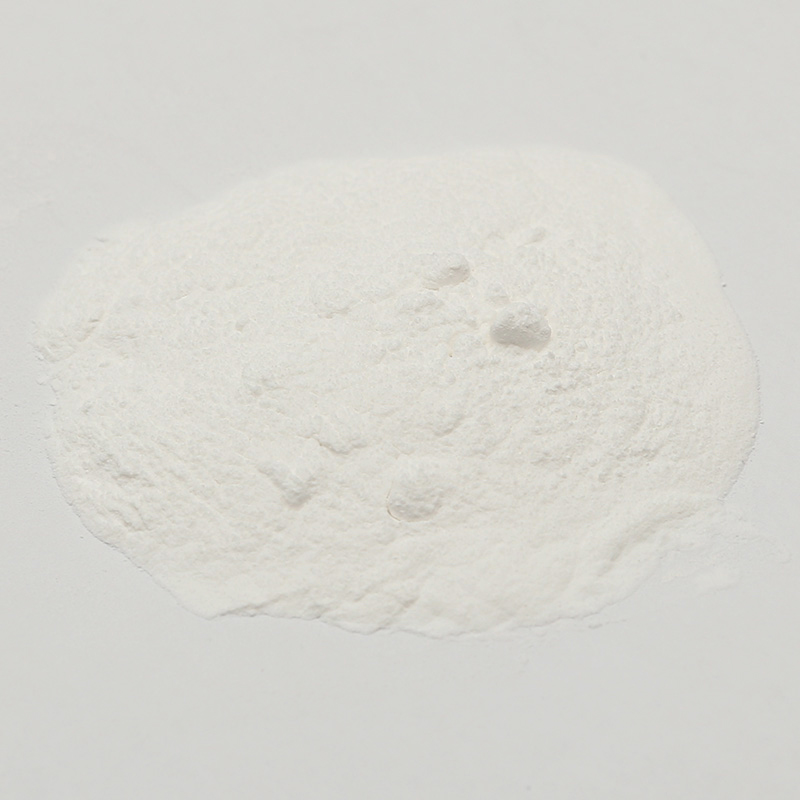

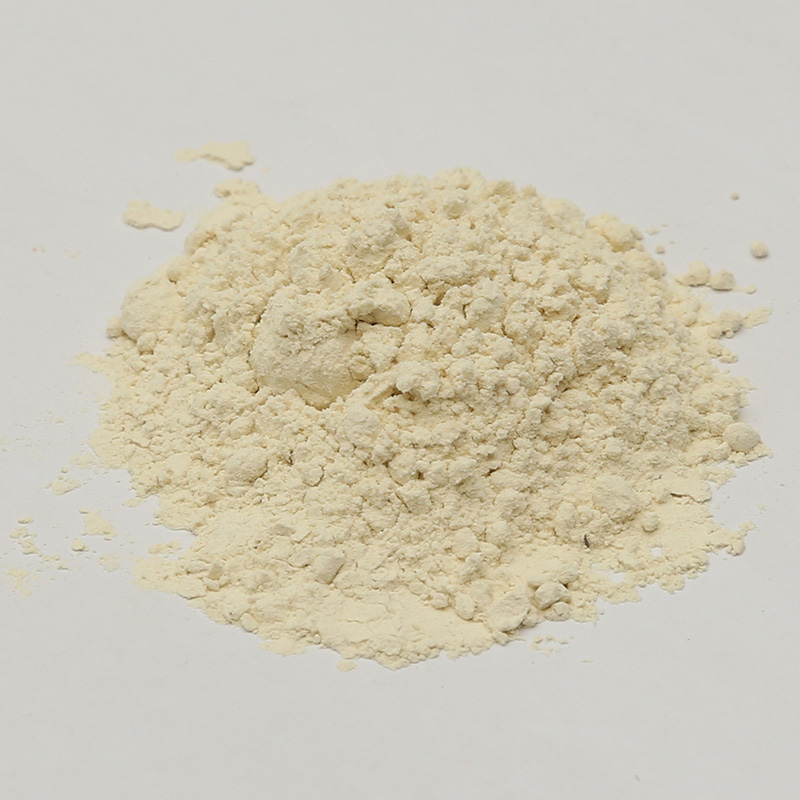

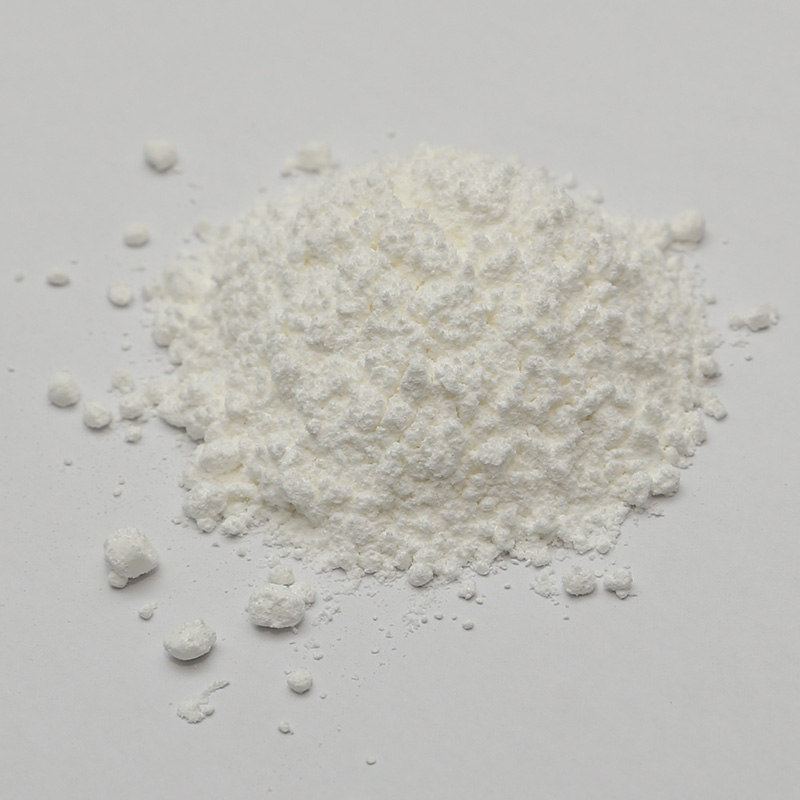

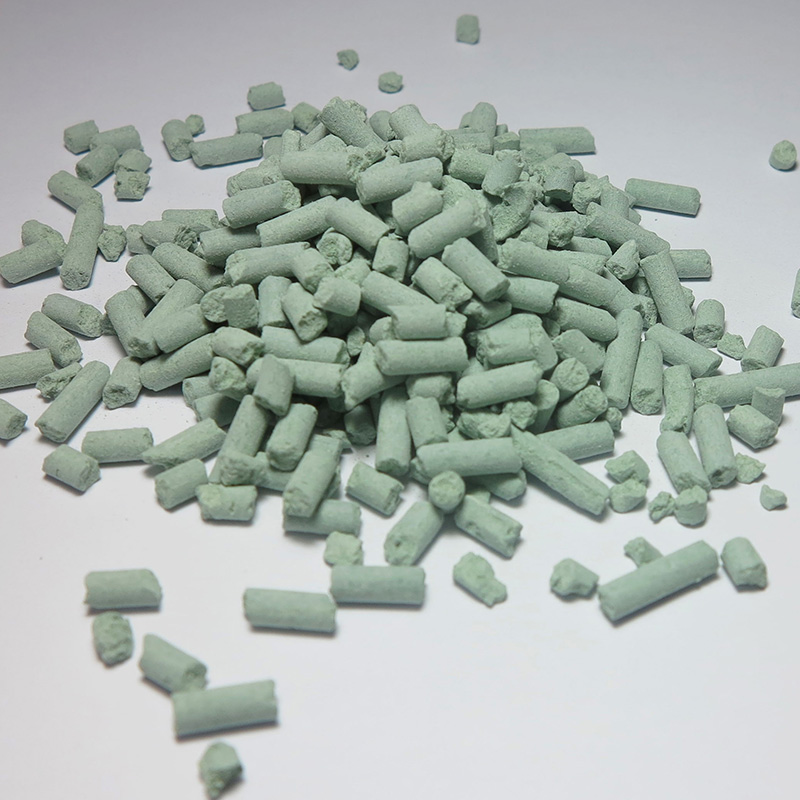

Selecting the correct type of rubber antioxidant agent is key. There are several categories, including phenolic antioxidants, amine antioxidants, phosphites, and natural antioxidants. Each type interacts differently with rubber polymers and offers unique protective mechanisms. For example, phenolic antioxidants are often chosen for their ability to neutralize free radicals effectively, making them suitable for natural rubber formulations. On the other hand, amine antioxidants provide robust protection in synthetic rubber exposed to higher temperatures. Knowing these differences helps manufacturers blend the right antioxidant agent into their rubber formulations.

The concentration of the rubber antioxidant agent is another important factor in optimization. Adding too little may not provide adequate protection, while too much can affect the physical properties of the rubber, such as elasticity or color. Manufacturers often perform tests to determine the ideal amount that balances protection and performance. This careful calibration ensures that the rubber remains flexible and durable without unnecessary additive waste.

Compatibility with other ingredients in the rubber formulation also influences the effectiveness of the rubber antioxidant agent. Rubber compounds typically include fillers, plasticizers, curing agents, and other additives. Some antioxidant agents work better with specific fillers or curing systems. A thorough understanding of how these components interact helps prevent issues such as additive migration or interference with vulcanization, which could compromise the final product.

Testing and quality control are essential parts of optimizing rubber formulations. Once a rubber antioxidant agent is selected and added, manufacturers conduct aging tests, ozone resistance checks, and mechanical performance evaluations. These tests simulate real-world conditions to ensure that the antioxidant agent performs as expected over time. Feedback from testing guides further adjustments to the formulation, helping achieve the desired balance of durability and flexibility.

Environmental considerations are increasingly important in choosing a rubber antioxidant agent. Sustainable manufacturing practices encourage the use of antioxidant agents with lower toxicity and better biodegradability. Optimizing rubber formulations with greener antioxidant agents supports not only product performance but also environmental goals, responding to growing demand for eco-friendly materials.

Processing conditions during manufacturing also affect how well a rubber antioxidant agent performs. High temperatures used during curing can impact the stability of some antioxidant agents. Selecting an agent that withstands processing conditions without losing effectiveness ensures that the final rubber product retains its protective benefits. Manufacturers may need to adjust curing times or temperatures to accommodate the properties of the chosen antioxidant.

A practical approach to optimization involves combining different types of rubber antioxidant agents. This synergy can enhance overall protection by targeting multiple degradation pathways simultaneously. For instance, pairing a phenolic antioxidant with a phosphite can provide both free radical scavenging and peroxide decomposition. This combination helps rubber components withstand a wider range of environmental challenges.

In everyday products, the benefits of optimized rubber formulations with the right rubber antioxidant agent are clear. Tires that resist cracking, seals that maintain flexibility, and hoses that withstand heat all contribute to safer, longer-lasting goods.

In summary, optimizing rubber formulations with the right rubber antioxidant agent involves careful selection based on application needs, additive type, concentration, and compatibility.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体