Enhancing Stability Through Uniform Dispersion

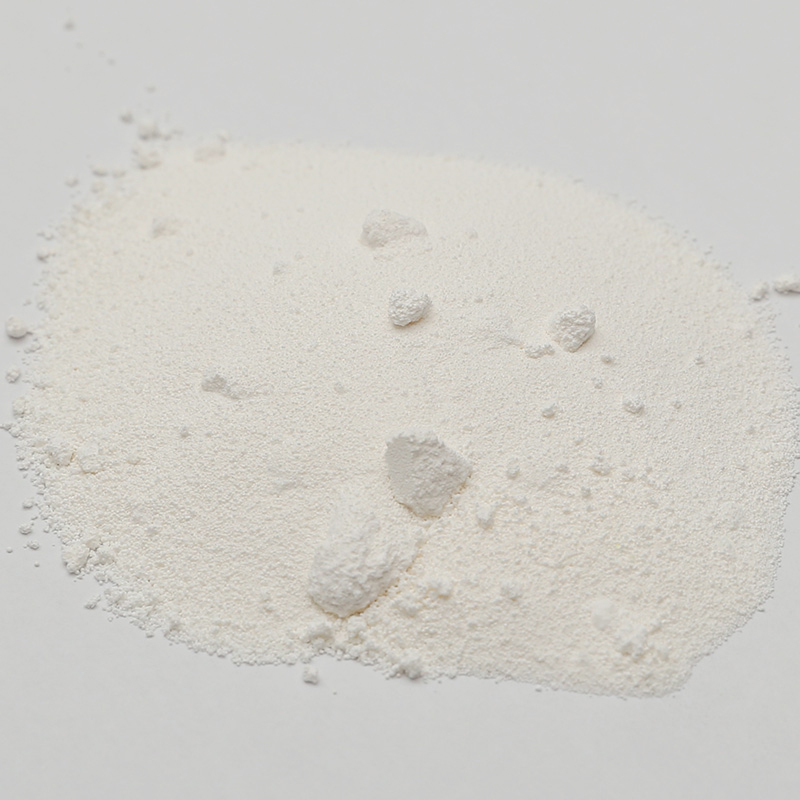

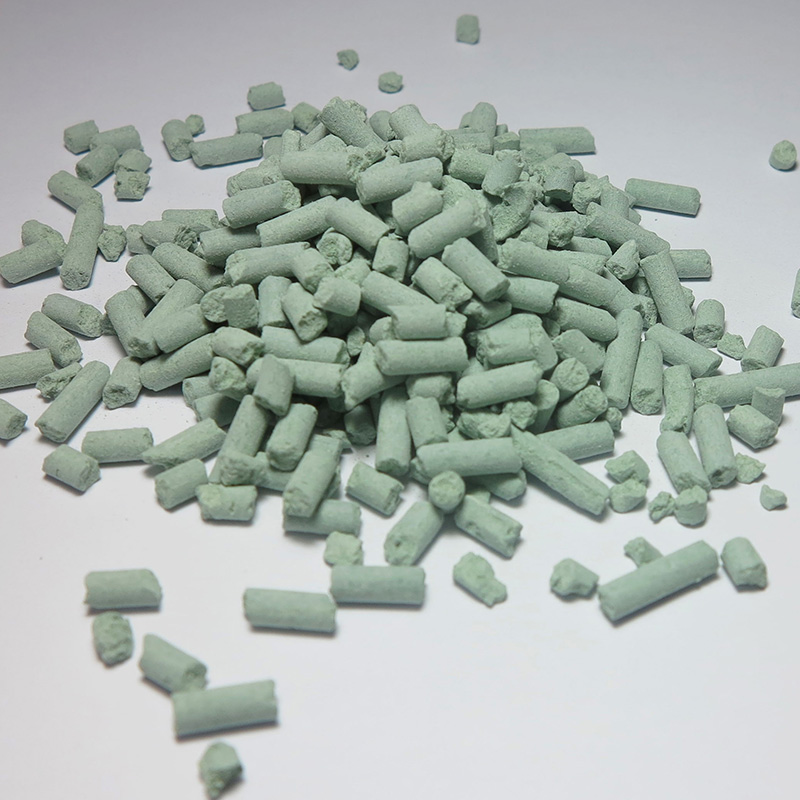

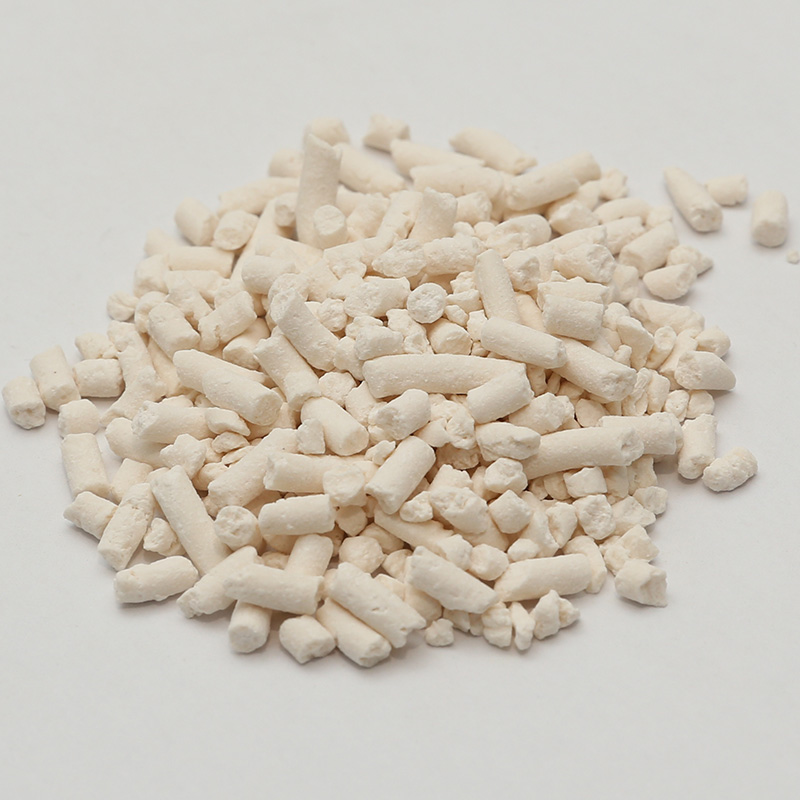

In modern industrial production, maintaining a consistent product over time is essential for ensuring performance, consumer trust, and regulatory compliance. Whether the final product is a food emulsion, cosmetic cream, or pharmaceutical suspension, the presence of multiple phases—such as oil and water, solids and liquids—poses a challenge to long-term stability. This is where the role of a homogenizing agent becomes crucial. Used early in the formulation process, it assists in breaking down larger droplets or particles into much smaller, uniformly distributed units. This uniform dispersion inhibits separation caused by density differences or gravitational effects, which commonly occur in unhomogenized systems. By reducing particle size and promoting a stable phase distribution, the agent significantly improves the product’s ability to maintain its original structure and composition across storage periods.

Improving Texture and Visual Appeal Through Uniformity

A visually appealing and texturally smooth product is critical, especially in consumer-focused industries such as skincare, food, and beverages. When the dispersion of particles or droplets in a product is uneven, it can result in visible separation, grittiness, or a curdled appearance—all of which detract from perceived quality. The homogenizing agent facilitates the creation of fine and evenly distributed particles, ensuring that creams remain smooth, dressings do not separate, and drinks do not settle into layers. Uniformity in texture is more than just an aesthetic feature; it directly contributes to consumer satisfaction and product usability. By avoiding clumps, floating particles, or sedimentation, the product retains its expected characteristics throughout its shelf life and under a variety of storage conditions.

Functional Performance Across Variable Conditions

A well-homogenized product also displays better resilience to physical and environmental stress. During storage and transport, products often face temperature fluctuations, vibration, and pressure changes. In the absence of proper homogenization, these factors may accelerate phase separation or destabilize the product’s internal structure. The inclusion of a homogenizing agent allows the formulation to resist these stressors more effectively by providing structural reinforcement at the microscopic level. This is particularly important in pharmaceuticals, where consistent bioavailability is tied to particle distribution, and in food products, where phase separation could impact taste or safety. Moreover, by contributing to more uniform ingredient distribution, the agent helps ensure that active components—such as vitamins, medications, or preservatives—are evenly present in every dose or serving.

Compatibility With Other Additives and Formula Flexibility

Another way homogenizing agents contribute to overall stability and uniformity is through their ability to work in synergy with other ingredients. Many modern formulations require multiple additives: emulsifiers, thickeners, stabilizers, and preservatives. A high-quality homogenizing agent supports the effective integration of these components, reducing the risk of ingredient incompatibility or formulation failure. Furthermore, the flexibility provided by homogenization technology enables manufacturers to experiment with a wider range of oils, waxes, or powders, broadening the spectrum of available product textures and functions without sacrificing stability. This adaptability is especially valuable in clean-label formulations, where synthetic stabilizers are avoided, and mechanical homogenization must bear a larger share of the workload.

Ultimately, a product's ability to remain consistent, stable, and visually appealing is closely tied to the effectiveness of the homogenization process. While many factors contribute to product integrity, the use of a homogenizing agent provides an essential foundation for creating smooth, stable, and well-integrated formulations. From fine particle dispersion to resilience under stress and compatibility with complex ingredients, this invisible player in the formulation process has a visible impact on product quality

English

English Português

Português Español

Español русский

русский 中文简体

中文简体