Custom Cheap Rubber Peptizing Agent Vulcanization Accelerator Price

Rubber compounds are widely used in industries ranging from automotive to footwear due to their unique combination of flexibility, durability, and resilience. However, the performance of these compounds can be heavily influenced by the processing methods and materials used during their manufacture. One important element that contributes to the optimization of rubber compounds is the use of peptizing agents. They are chemicals that help break down the rubber’s molecular structure, making the compound more processable and improving its final properties. In this article, we will explore how Custom Peptizing agents enhance the performance of rubber compounds.

A peptizing agent's primary role is to reduce the viscosity of rubber, which is often high in its raw form. Natural rubber, for instance, is harvested in a solid and sticky state, which can make it difficult to process in manufacturing environments. They help lower the viscosity by disrupting the polymer chains, allowing the rubber to flow more easily during processes like extrusion and molding. By reducing viscosity, they make the rubber compound more workable, ensuring smoother processing and higher efficiency during production.

In addition to improving processability, peptizing agents also influence the distribution of other ingredients within the rubber compound. The production of rubber compounds typically involves the addition of various chemicals, such as fillers, plasticizers, and curing agents, which are added to achieve specific properties like strength, elasticity, and durability. They help in uniformly dispersing these ingredients throughout the rubber matrix. When additives are properly mixed, the final product exhibits more consistent mechanical properties, ensuring that the rubber performs reliably in its intended application.

Another benefit of peptizing agents is their ability to improve the uniformity of the rubber compound. When raw rubber is processed without aid, the resulting compound can sometimes display uneven characteristics, such as poor flowability or inconsistent hardness. Peptizing agents facilitate a more consistent molecular structure, reducing these issues and allowing the compound to maintain uniformity in properties such as tensile strength, elasticity, and resistance to wear. The result is a rubber compound that performs better across a wide range of conditions, from high-heat environments to situations involving constant abrasion.

Cheap Rubber Accelerators can also play a role in improving the curing process of rubber compounds. Curing, or vulcanization, is a critical stage in rubber processing that involves the cross-linking of polymer chains to form a stable, elastic material. The presence of it helps ensure that the curing agents are more evenly distributed throughout the compound. This facilitates a more efficient curing process, resulting in a more uniform crosslinking and a final rubber product with ideal elasticity and mechanical properties. An efficient curing process also reduces the chances of defects such as uneven hardness or poor resilience.

In terms of mechanical properties, peptizing agents enhance the strength and durability of rubber compounds. The improved dispersion of fillers and additives, aided by it, results in a better reinforcing effect. Fillers like carbon black or silica are added to rubber compounds to improve their tensile strength, wear resistance, and thermal stability. By ensuring that these fillers are well-dispersed, they help enhance their reinforcing effect, resulting in a rubber compound that performs better under stress and over time. This improved reinforcement can be especially beneficial for applications such as tires, seals, and gaskets, where the material is subject to heavy loads and constant wear.

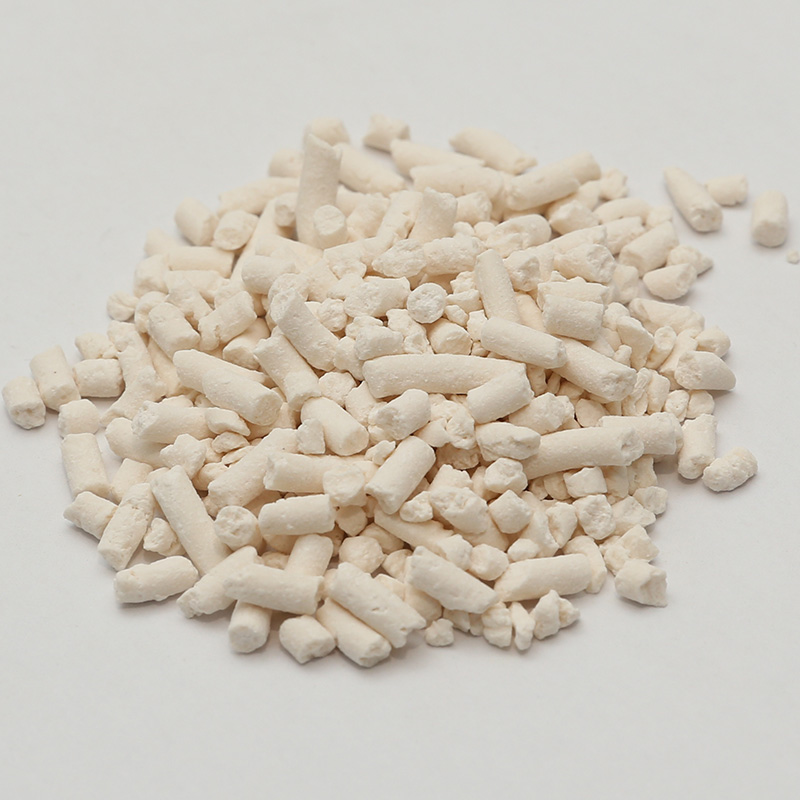

Peptizing agents also have a role in enhancing the processing efficiency of rubber compounds, resulting in shorter cycle times and lower energy consumption. When rubber is easier to process and mold, manufacturers can produce more products in less time, which contributes to increased production capacity. Furthermore, the reduced viscosity and enhanced flow properties of the compound can result in lower processing temperatures, which in turn can save energy and reduce overall costs. This makes the use of them an attractive solution for manufacturers seeking to improve both the performance and the cost-effectiveness of their production processes.

In addition, Vulcanization Accelerator Prices can improve the sustainability of rubber production. By facilitating better dispersion of additives and improving processing efficiency, they contribute to reducing material waste during manufacturing. More efficient processing also means that fewer chemicals are needed, and less energy is consumed, which can help reduce the environmental footprint of rubber production.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体