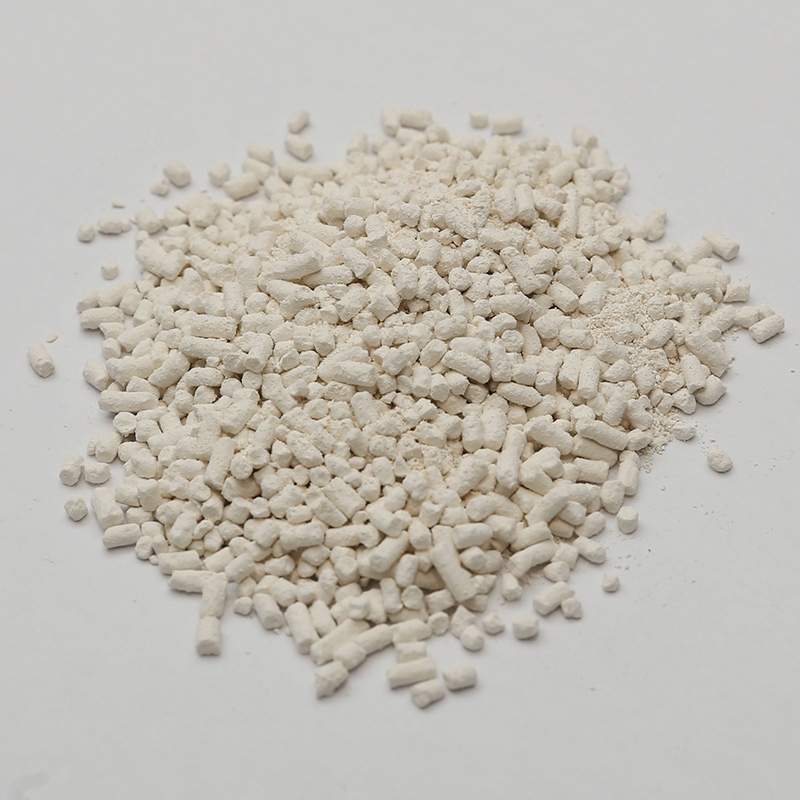

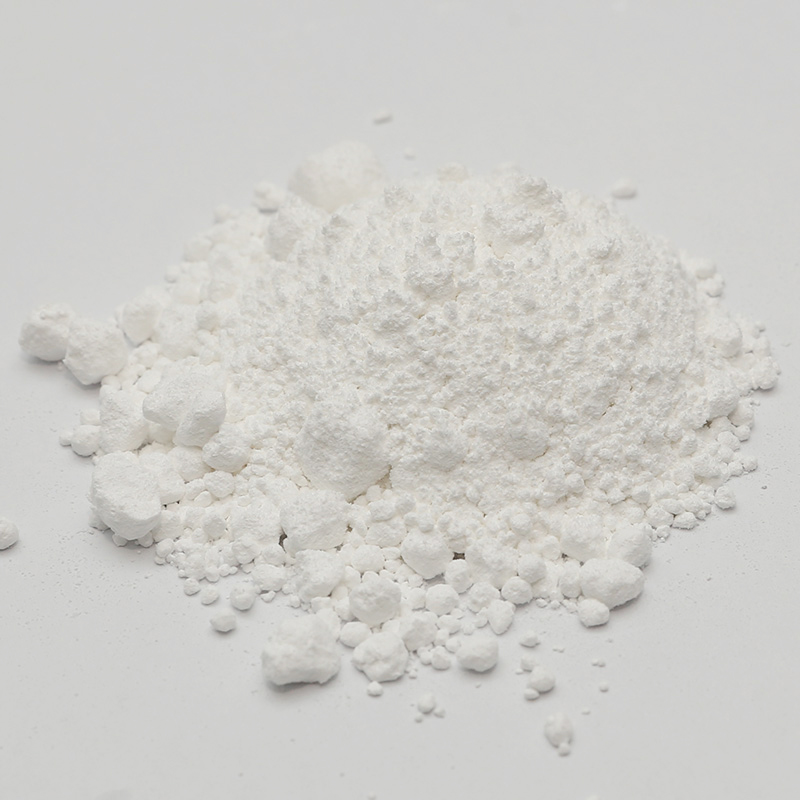

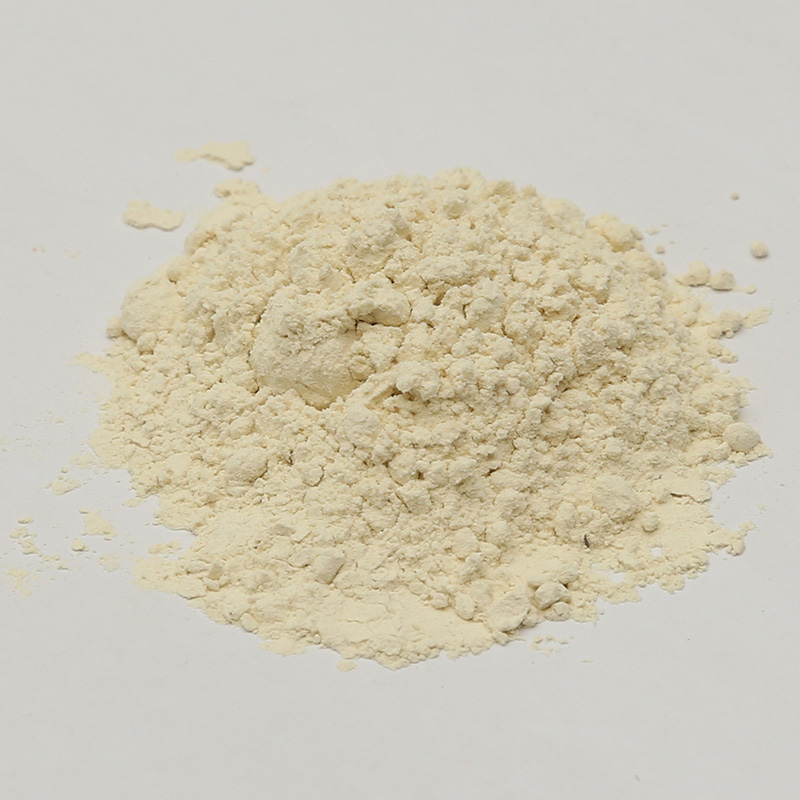

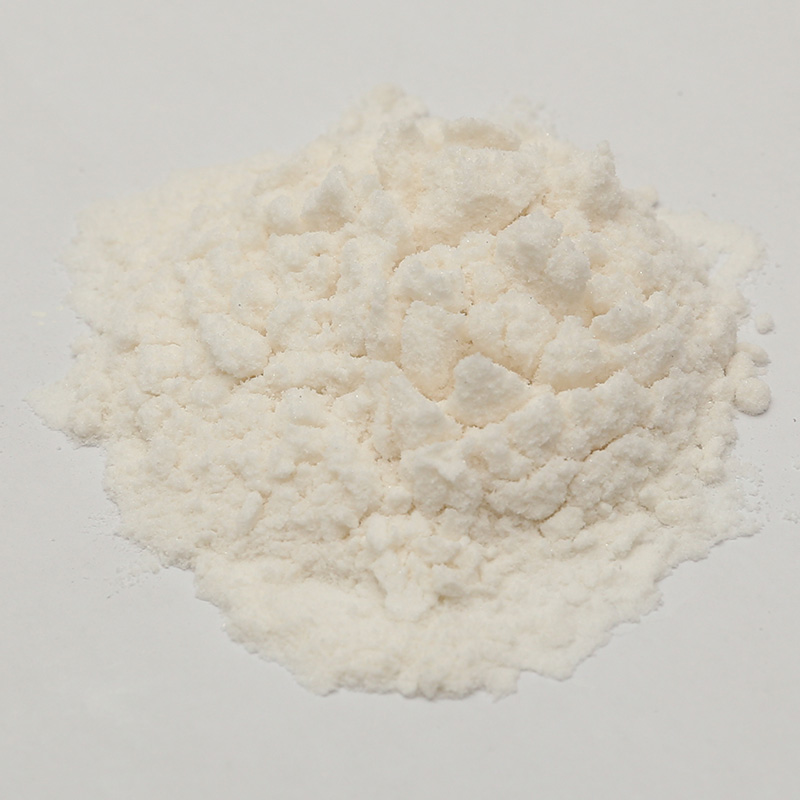

China Wholesale Peptizing Adhesive Chemical Agent Additives Factory

Rubber, whether natural or synthetic, plays a critical role in a variety of industries due to its unique combination of flexibility, durability, and resilience. However, to fully harness the properties of rubber, the molecular structure must be manipulated during processing. One of the key tools used to achieve this is the peptizing agent. They are chemical compounds that influence the molecular structure of rubber, making it easier to process and enhancing the performance of the final product. This article explores the science behind China peptizing agents and their effect on rubber's molecular structure.

The molecular structure of rubber consists of long polymer chains that are entangled and held together by intermolecular forces, such as van der Waals forces or hydrogen bonds. These forces contribute to the rubber's high viscosity in its raw form, which makes it difficult to manipulate during manufacturing. Peptizing agents work by breaking down these intermolecular bonds and reducing the rubber’s viscosity, thus making it easier to process.

The main role of a peptizing agent is to disrupt the rubber's molecular network without causing complete degradation. By cleaving certain bonds within the polymer chains, it reduces the molecular weight of the rubber. The reduction in molecular weight lowers the viscosity of the material, allowing for smoother processing. This makes it easier to mix the rubber with other additives, such as curing agents, fillers, and plasticizers, ensuring a more uniform dispersion of these ingredients throughout the rubber matrix.

The action of peptizing agents on the rubber molecular structure is largely driven by the chemical nature of the agent itself. They are sulfur-containing compounds, fatty acids, or aromatic substances that interact with the polymer chains through chemical or physical forces. These agents may break the bonds between polymer chains by either physical or chemical means, depending on their nature and concentration. Some work by absorbing into the rubber matrix, while others may release small amounts of heat or energy that aid in the disruption of the molecular structure.

The molecular changes induced by peptizing agents also have an effect on the rubber's rheological properties. The viscosity of the rubber compound decreases as the molecular structure is broken down, making it more fluid and easier to process in manufacturing equipment such as extruders, calenders, or injection molding machines. This reduction in viscosity improves the flowability of the rubber, allowing for more efficient processing at lower temperatures, which can reduce energy consumption and cycle times in production.

In addition to improving processability, Wholesale Adhesive Additives can enhance the mechanical properties of rubber. The uniform distribution of additives made possible by peptization results in better performance characteristics, such as improved tensile strength, elasticity, and resistance to wear. When rubber compounds are mixed and processed with a peptizing agent, the consistency of the molecular structure results in a more uniform distribution of reinforcing fillers like carbon black or silica. These fillers are added to enhance the rubber’s durability, and their even dispersion ensures that the rubber compound exhibits ideal properties, such as greater strength and longevity.

Peptizing agents also play an important role in the curing process of rubber. Curing, or vulcanization, is the process where sulfur or other crosslinking agents are used to form links between the polymer chains, creating a more durable and elastic material. The presence of it ensures that curing agents are distributed evenly throughout the rubber compound, resulting in a more uniform vulcanization process.

In conclusion, the Chemical Additives Factory plays a critical role in altering the molecular structure of rubber to improve its processability, enhance its mechanical properties, and ensure uniformity in the final product. By reducing viscosity and improving the dispersion of additives, they make the rubber easier to handle during manufacturing and contribute to its improved performance in applications such as tires, seals, and gaskets. The controlled molecular changes induced by peptizing agents allow manufacturers to achieve the desired balance between processability and performance, making these agents an essential tool in the rubber industry. As the demand for high-performance rubber products continues to grow, the role of peptizing agents will remain crucial in achieving ideal results in rubber processing.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体