China Cheap Chemical Vulcanizing Rubber Vulcanized Liquid Products Wholesaler

Custom rubber molding is a specialized process that requires precision and expertise to create high-quality rubber products tailored to specific needs. One of the key factors in achieving excellence in this field is the application of chemical vulcanizing. This process plays a crucial role in determining the physical properties and performance of rubber products. In this article, we will explore the advantages of China chemical vulcanizing in the context of custom rubber molding, highlighting its impact on product quality, durability, and versatility.

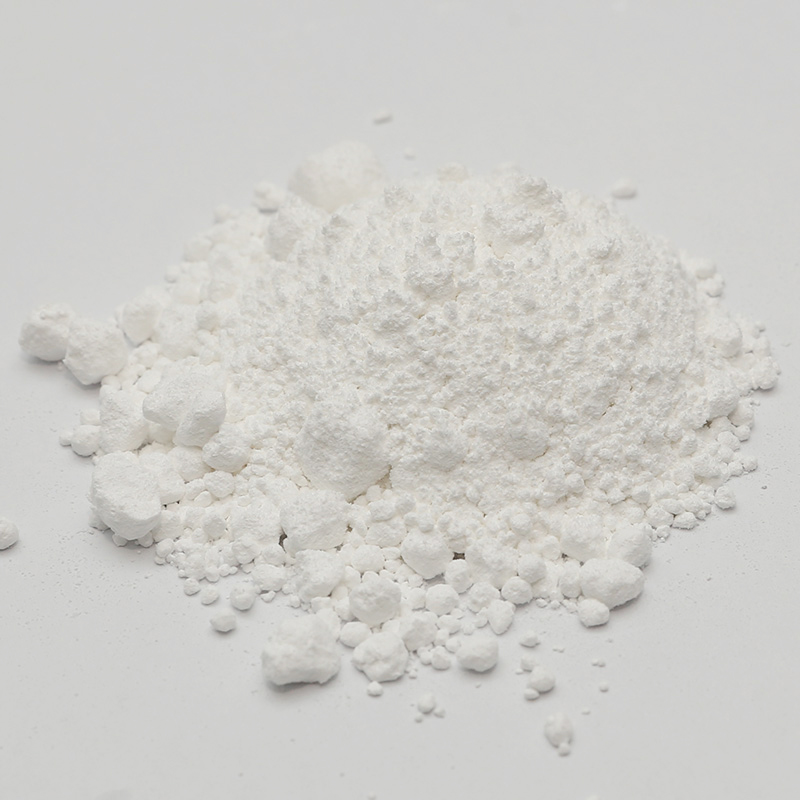

Chemical vulcanizing is a process that involves the use of specific chemicals, known as vulcanizing agents, to induce cross-linking within the rubber matrix. This cross-linking is essential for enhancing the elasticity, strength, and resilience of rubber. By controlling the chemical reactions that occur during vulcanization, manufacturers can tailor the properties of rubber to meet the exacting demands of custom molding applications.

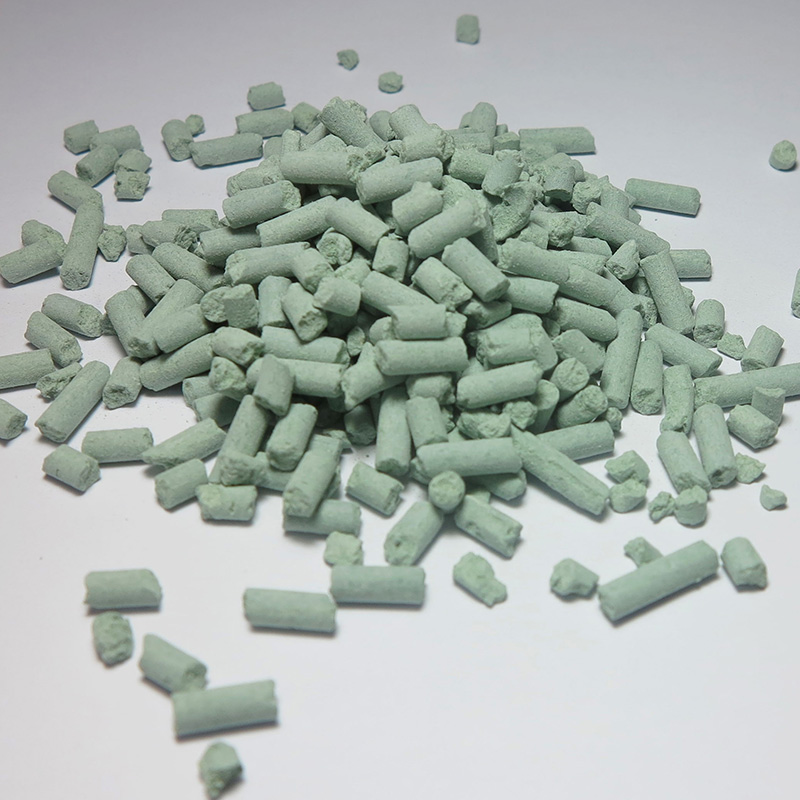

Advantages of Chemical Vulcanizing in Custom Rubber Molding. One of the primary advantages of its ability to significantly improve the durability of rubber products. Through the process, rubber gains resistance to wear and tear, making it suitable for applications where the product will be subjected to continuous use or harsh conditions. This is particularly important in industries such as automotive, where rubber components must withstand the rigors of daily operation.

Chemical vulcanizing allows for the fine-tuning of rubber's elasticity, which is vital for custom rubber molding. By adjusting the degree of cross-linking, manufacturers can create rubber parts that have the precise level of flexibility needed for their specific application. This is crucial for ensuring that the rubber product can withstand the stresses of its intended use without becoming brittle or losing its shape.

The hardness of rubber is another property that can be controlled through Cheap Vulcanized Rubber Products. By altering the formulation and process parameters, rubber can be made to have varying degrees of hardness, from soft and pliable to hard and rigid. This flexibility is invaluable in custom rubber molding, where products need to meet specific hardness requirements for performance.

Many rubber products are exposed to high temperatures during their service life. Chemical vulcanizing can improve a rubber's resistance to heat, which is essential for maintaining its structural integrity and performance under such conditions. This advantage is particularly relevant for applications in the aerospace, automotive, and industrial sectors, where heat resistance is a critical factor.

Chemical vulcanizing can also enhance a rubber's resistance to various chemicals, making it suitable for use in environments where exposure to chemicals is a concern. This is particularly beneficial for custom rubber molding applications in the chemical processing and pharmaceutical industries, where products may come into contact with corrosive substances.

The use of chemical vulcanizing in custom rubber molding ensures consistent quality across all products. By controlling the chemical reactions that occur during vulcanization, manufacturers can produce rubber parts with uniform properties, which is essential for maintaining performance standards and reducing waste due to product variability.

The process of chemical vulcanizing can be more cost-effective than other methods of rubber hardening, such as thermal vulcanizing. Reducing the need for high-energy processes and equipment can help manufacturers save on production costs while still achieving the desired properties in their rubber products.

Vulcanized Liquid Wholesaler offers a wide range of applications in custom rubber molding, from seals and gaskets to automotive parts and industrial components. Its versatility allows manufacturers to create a diverse array of products that meet the specific needs of their customers.

The precision that chemical vulcanizing offers in controlling rubber properties is unmatched. Manufacturers can fine-tune the properties of rubber to meet the exact specifications of their custom molding projects, ensuring that the final product meets the performance criteria required.

As new rubber materials are developed, chemical vulcanizing can be adapted to work with these materials, allowing for the creation of innovative products with enhanced properties. This adaptability is crucial in a rapidly evolving industry where staying ahead of the competition is key.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体