China Custom Tech Vulcanizing Fluid Agent Manufacturer

In the realm of medical technology, the use of rubber products is ubiquitous, ranging from surgical gloves to catheters and seals in medical devices. The quality and safety of these products are of paramount importance and the role of Vulcanizing Agents in ensuring these attributes cannot be overstated. Vulcanizing Agents are the cornerstone of the rubber industry, as they are responsible for the cross-linking process that gives rubber its strength, durability, and elasticity. This article delves into the significance of China Vulcanizing Agents in the production of medical rubber products and how they contribute to the overall performance and safety of these critical components.

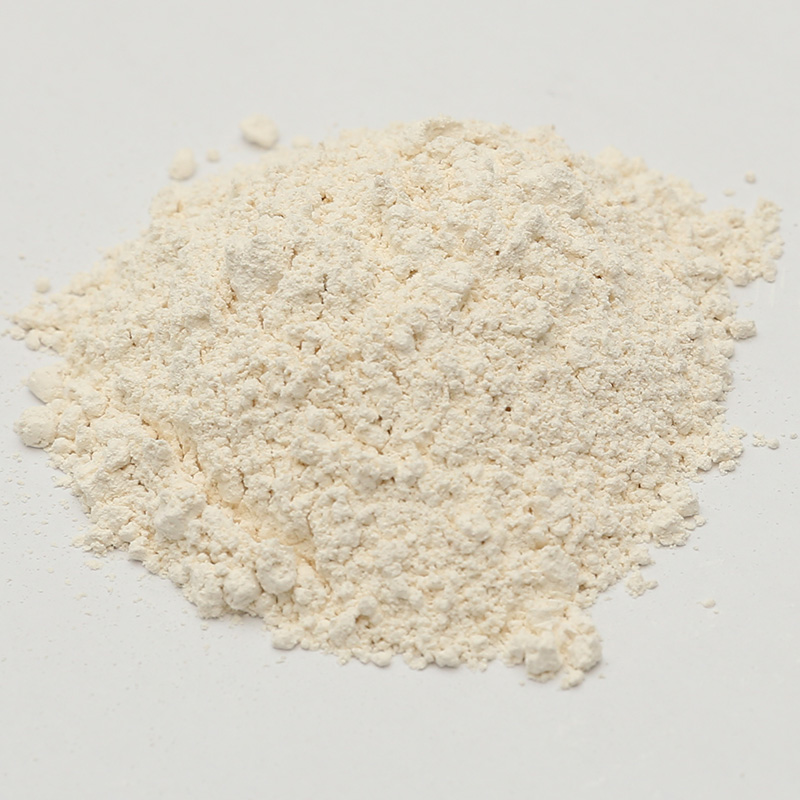

Vulcanizing Agents are chemical compounds that facilitate the cross-linking of polymer chains in rubber, a process known as vulcanization. This process is essential for transforming raw rubber into a stable, usable material with enhanced physical properties. The selection of the appropriate one is crucial, as it directly impacts the properties of the rubber product. In the medical industry, where precision and reliability are non-negotiable, the choice of Vulcanizing Agent is even more critical.

The use of Vulcanizing Agents in medical rubber products is not limited to mere cross-linking. They also play a pivotal role in enhancing the material's resistance to aging, flexibility, and resistance to various environmental factors. For instance, medical-grade rubber must be resistant to body fluids, and sterilization processes, and maintain its integrity over extended periods. The right can ensure that these properties are achieved, thereby ensuring the safety and efficacy of the medical device.

In the medical field, regulatory compliance is a must, and the use of Vulcanizing Agents must adhere to strict guidelines set by health authorities such as the FDA. Certain Vulcanizing Agents may leach out of the rubber over time, posing a risk to patients. Therefore, it is imperative to use biocompatible them that meet higher safety standards. The choice must also consider the potential for allergic reactions or sensitivities in patients, further emphasizing the importance of careful selection.

There are various types of Vulcanizing Agents used in the medical industry, each with its unique properties and applications. Commonly used Vulcanizing Agents include sulfur, peroxides, and metal oxides. Sulfur is a traditional it that provides physical properties but may not be suitable for all medical applications due to potential leaching concerns. Peroxides, on the other hand, offer a cleaner cure with less risk of leaching but can be more challenging to process. Metal oxides are often used in specialized applications where high heat resistance is required.

The field of Custom Vulcanizing Fluid technology is continuously evolving, with researchers developing new compounds that offer improved performance and safety profiles. These innovations are particularly important in the medical industry, where the demand for high-performance materials is ever-increasing. New ones are being developed to meet the challenges of new medical device designs, improved sterilization techniques, and the need for longer-lasting, more reliable products.

As medical technology advances, the role of Vulcanizing Agents in medical rubber products will only become more critical. The development of new materials, the need for more complex device designs, and the push for greater patient safety will drive the demand for advanced Vulcanizing Agents. The future of medical rubber products will likely see a shift towards more specialized them that can meet the unique challenges of each application.

In conclusion, Tech Vulcanizing Fluid Manufacturers are indispensable in the production of medical rubber products. They not only provide the necessary strength and durability but also ensure the safety and reliability of these critical components. As the medical industry continues to evolve, the development and selection of them will remain a key area of focus, ensuring that higher standards of patient care are maintained. The importance of Vulcanizing Agents in medical rubber products cannot be overstated, as they are the silent heroes behind the scenes, enabling the creation of life-saving and life-enhancing medical devices.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体