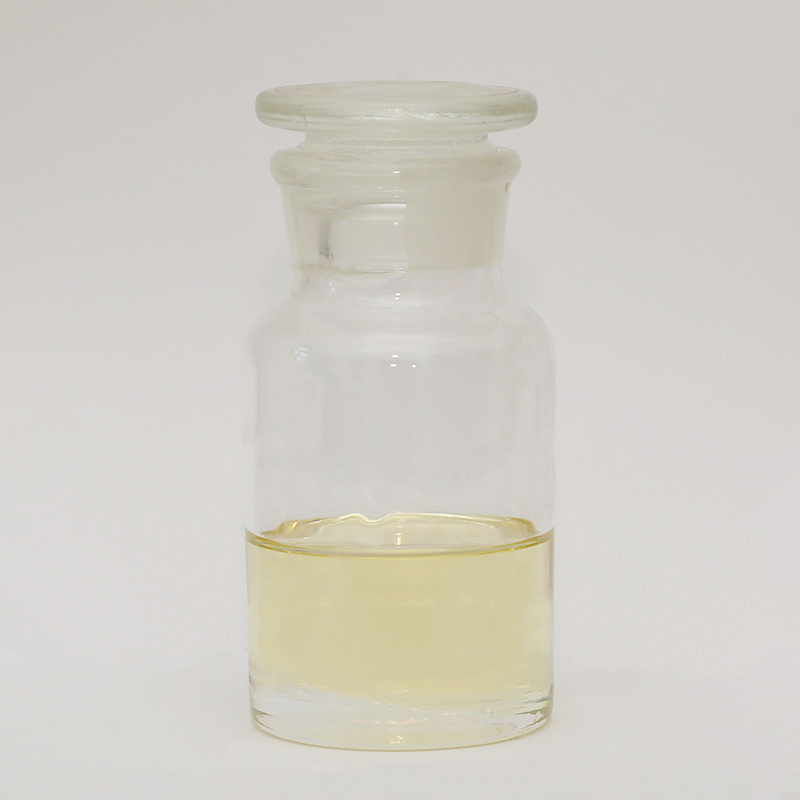

Sale OEM Chemical Vulcanizing Agent Vulcanization Fluid Maker

In the realm of modern tire production, the term "Vulcanizing Agent" is synonymous with the very essence of quality and durability. Vulcanizing agents are the unsung heroes of the tire industry, playing a pivotal role in the manufacturing process. They are the chemical catalysts that transform raw rubber into the resilient, long-lasting material that we rely on for our vehicles.

Vulcanization is a chemical process that involves the cross-linking of polymer chains in rubber, which significantly enhances its strength, elasticity, and resistance to heat and degradation. The primary Vulcanizing Agent used in this process is sulfur, although other agents such as peroxides and metal oxides are also employed for specific applications. The use of it is crucial as it determines the properties of the rubber, which in turn affects the performance and lifespan of the tire.

Tire manufacturers rely heavily on Vulcanizing Agents to ensure that their products meet the stringent standards required for safety and performance. The process of vulcanization involves heating the rubber compound, which includes it, to a specific temperature. This heat activates the agent, causing the rubber molecules to bond and form a three-dimensional network. The result is a tire that is both strong and flexible, capable of withstanding the rigors of road travel.

There are several types of Vulcanizing Agents used in the tire industry, each with its unique properties and applications. Sulfur is common, providing strength and elasticity to the rubber. It is used in the production of passenger car tires, truck tires, and off-road tires. Peroxides, on the other hand, are used for curing rubber at lower temperatures, which is beneficial for producing tires with specific performance characteristics, such as those used in racing or high-performance vehicles. Metal oxides are also employed as Sale Vulcanizing Agents, particularly in the production of tires that require resistance to heat, ozone, or chemicals.

The tire industry is constantly evolving, and with it, the development of new and improved Vulcanizing Agents. Researchers are exploring the use of nanomaterials and other advanced compounds to enhance the properties of rubber. These innovations aim to create tires that are not only more durable and efficient but also more environmentally friendly. The use of alternatives can reduce the environmental impact of tire production by reducing the use of harmful chemicals and reducing waste.

The choice of Vulcanizing Agent has a direct impact on the performance of the tire. A well-vulcanized tire will have a longer lifespan, better grip, and improved resistance to wear and tear. This is particularly important for tires used in demanding conditions, such as those found in commercial transportation or severe sports. The right Vulcanizing Agent ensures that the tire can withstand high speeds, heavy loads, and harsh weather conditions without compromising its integrity.

Quality control is a critical aspect of tire production, and the use of Vulcanizing Agents is a key factor in this process. Manufacturers must ensure that the correct type and amount of it is used to achieve the desired properties in the rubber. This involves rigorous testing and monitoring throughout the production process to ensure consistency and reliability. Any deviation in the use of it can result in substandard tires, which can pose a significant risk to road safety.

As the tire industry continues to grow and adapt to new challenges, the role of Vulcanizing Agents will remain central to the production process. With increasing demands for sustainability and performance, the development of new and improved ones will be essential. The tire industry will likely see a shift towards more eco-friendly and efficient OEM Chemical Vulcanizing Fluids, which will not only enhance tire performance but also reduce the environmental footprint of tire production.

In conclusion, Vulcanizing Agents are indispensable in modern tire production. They are the chemical key that unlocks the full potential of rubber, transforming it into a material that is both strong and flexible. The tire industry's reliance on them highlights the importance of continuous research and innovation in this field. As we look to the future, the development of new Vulcanization Fluid Makers will play a crucial role in meeting the evolving needs of the tire industry, ensuring that the tires we rely on for our transportation are safe, durable, and environmentally responsible.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体