Preserving Chemical Activity

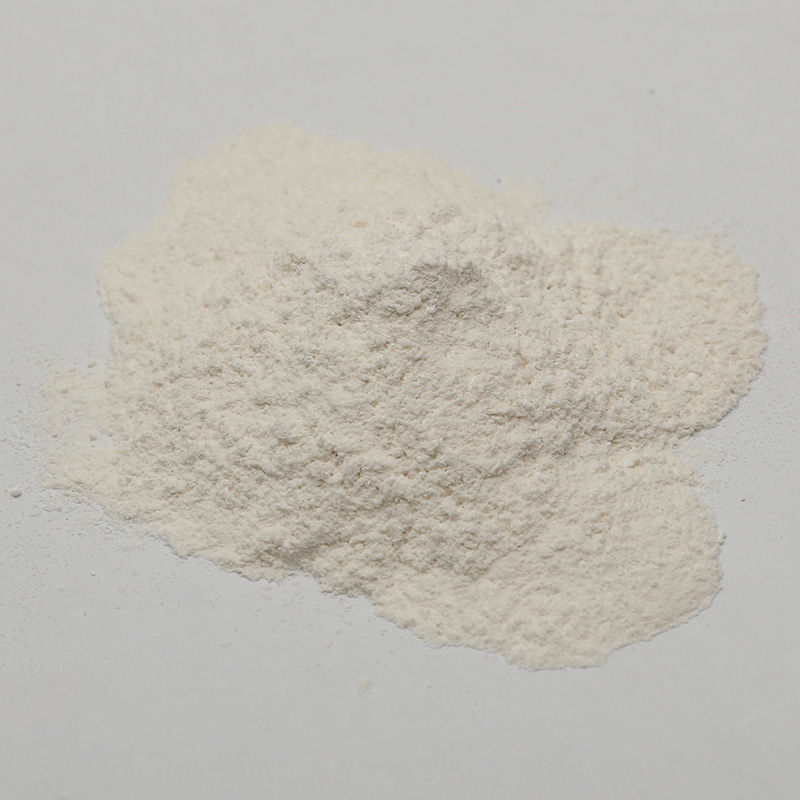

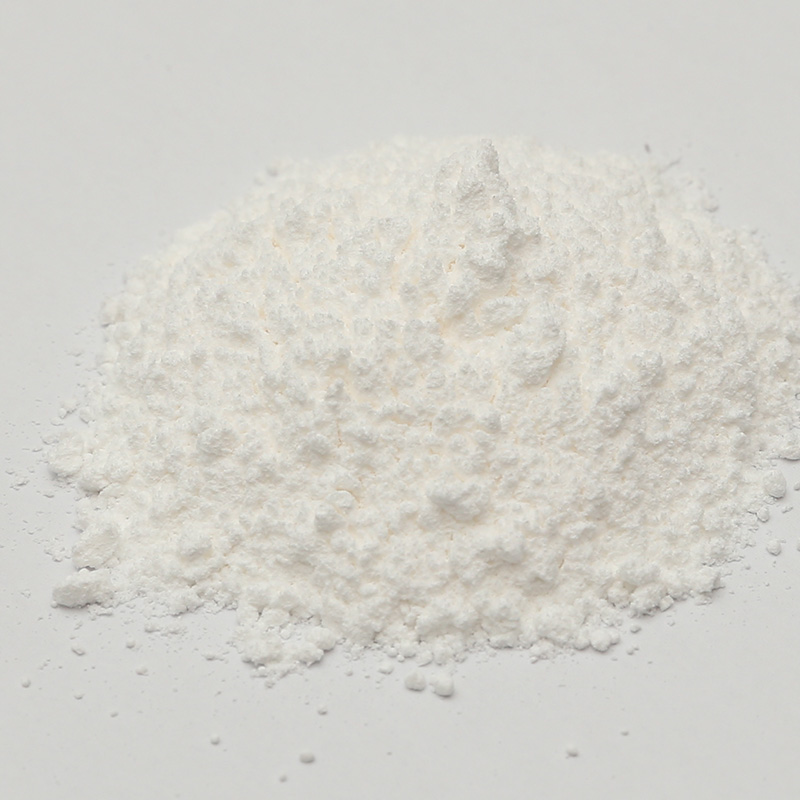

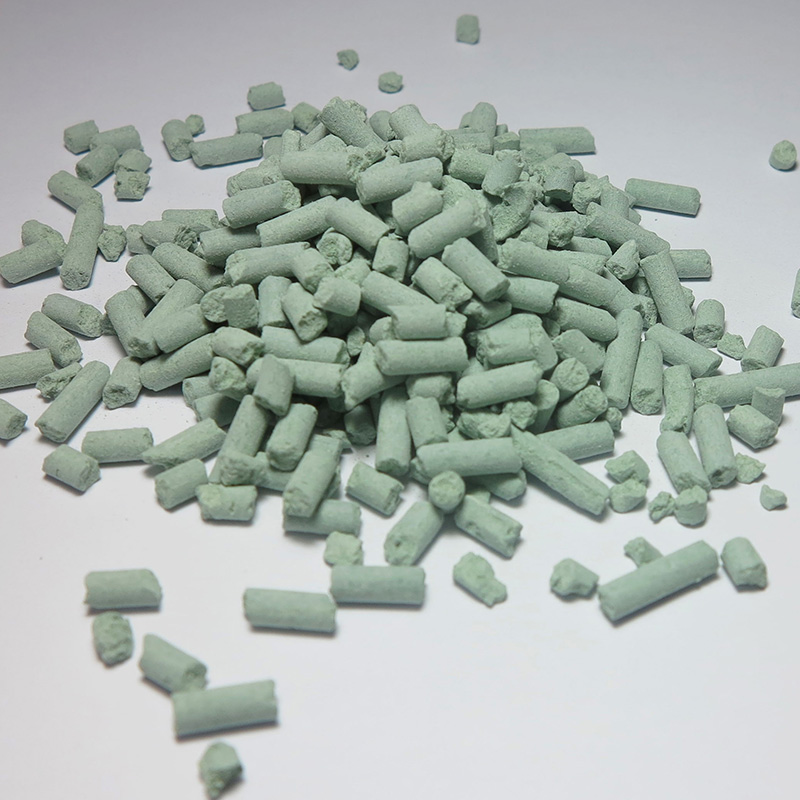

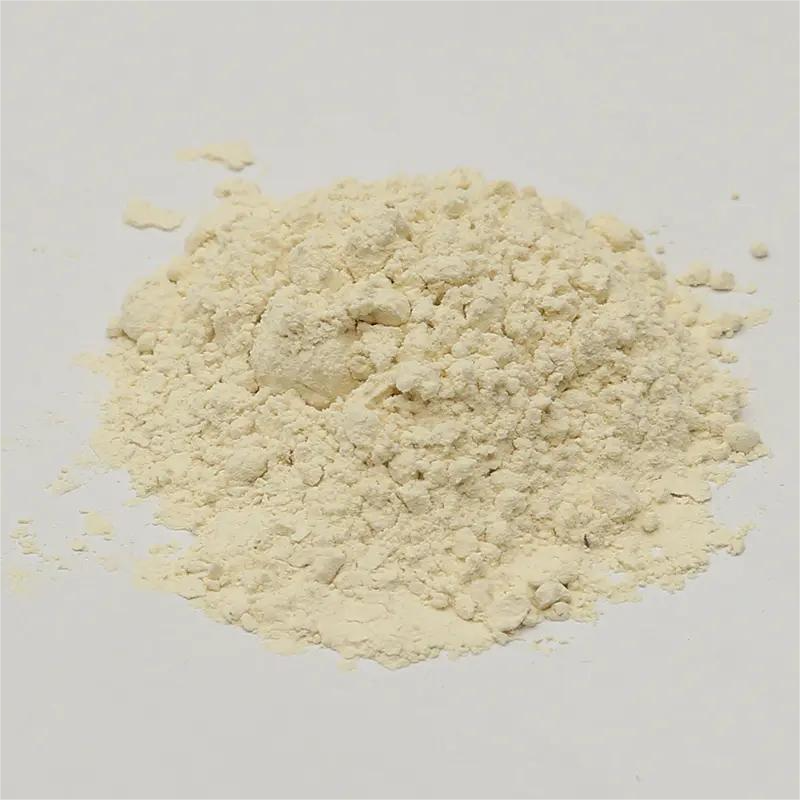

Rubber Accelerator plays a critical role in the rubber manufacturing process by speeding up vulcanization and improving the mechanical properties of the final product. Maintaining the chemical activity of these accelerators during storage is essential for consistent performance and production efficiency. Factors such as packaging type, environmental conditions, and handling practices can significantly influence the stability and effectiveness of the compound. Understanding these influences helps manufacturers and end-users maintain the quality and reliability of rubber products.

Influence of Packaging Materials

The type of packaging used for the Rubber Accelerator directly affects its stability. Airtight, moisture-resistant containers such as polyethylene drums, metal tins, or laminated bags protect against environmental exposure. Packaging that allows air or moisture ingress can accelerate hydrolysis, oxidation, or caking, causing reduced activity. The inclusion of desiccants or moisture absorbers within packaging can further safeguard against humidity, particularly in regions with high ambient moisture. Proper labeling, including storage instructions and shelf life, ensures that users handle the material appropriately, reducing degradation risks.

Storage Temperature and Environmental Conditions

Storage conditions, particularly temperature and humidity, play a critical role in preserving the activity of rubber accelerators. High temperatures can accelerate chemical reactions, causing decomposition or loss of effectiveness. Conversely, low temperatures may cause crystallization, aggregation, or separation in some formulations, affecting uniformity and dosing accuracy. Humidity is another key factor; exposure to moisture can trigger hydrolytic reactions or clumping, which reduces chemical reactivity and complicates handling. Maintaining stable, moderate temperatures and low humidity levels is essential for prolonging the shelf life and maintaining the chemical integrity of Rubber Accelerator.

Impact of Handling and Repeated Opening

Frequent handling or repeated opening of storage containers can expose the accelerator to air, moisture, and contaminants, compromising its activity over time. Using clean, dry tools and minimizing exposure to environmental elements during transfer or dosing are essential practices. Additionally, maintaining a clean storage environment and preventing cross-contamination with other chemicals reduces the risk of unintended reactions that may reduce the accelerator’s effectiveness. Proper operational protocols complement packaging and environmental controls to maintain suitable performance.

Shelf Life and Stability Considerations

Manufacturers typically provide guidelines for the shelf life and storage of Rubber Accelerator, which consider the combined effects of packaging, temperature, and humidity. Exceeding the recommended storage duration or ignoring these guidelines can result in reduced activity, slower vulcanization, and inconsistent rubber properties. Regular inspection of stored materials for signs of caking, discoloration, or moisture ingress can help identify compromised batches before use. By adhering to recommended storage practices, users can ensure that the accelerator retains its full chemical potential and its shelf life.

Ensuring Reliable Chemical Performance

Packaging and storage conditions have a significant impact on the activity of Rubber Accelerator. Moisture-resistant and airtight packaging, controlled temperature and humidity, and careful handling are crucial to preserving chemical stability. By following manufacturer-recommended storage guidelines and implementing protective measures, operators can maintain consistent vulcanization performance, improve production efficiency, and ensure the quality of rubber products. Awareness of these factors is essential for extending the effective life of the accelerator and minimizing waste in industrial applications.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体