The Importance of Chemical Stability

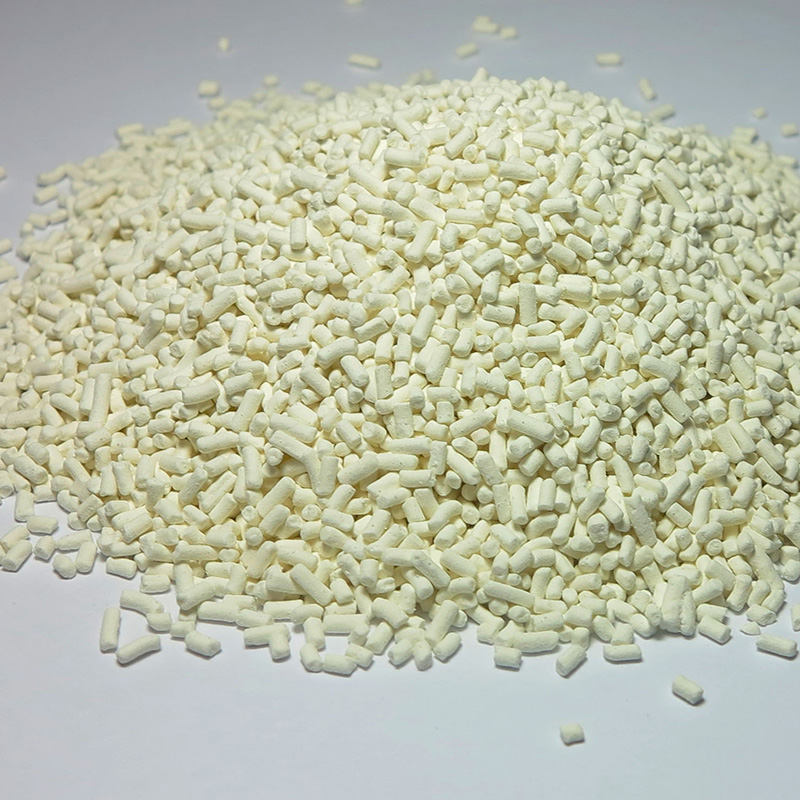

Rubber accelerators are vital additives in the rubber manufacturing process, enhancing vulcanization speed and improving the mechanical properties of the final product. However, their chemical stability can be sensitive to storage conditions. Exposure to moisture, fluctuating temperatures, or inadequate packaging can compromise the activity of these compounds, potentially causing uneven curing, reduced performance, and production inefficiencies. Understanding how storage environments influence the stability of Rubber Accelerator is essential to maintain its effectiveness and ensure consistent quality in rubber products.

Moisture Sensitivity and Its Consequences

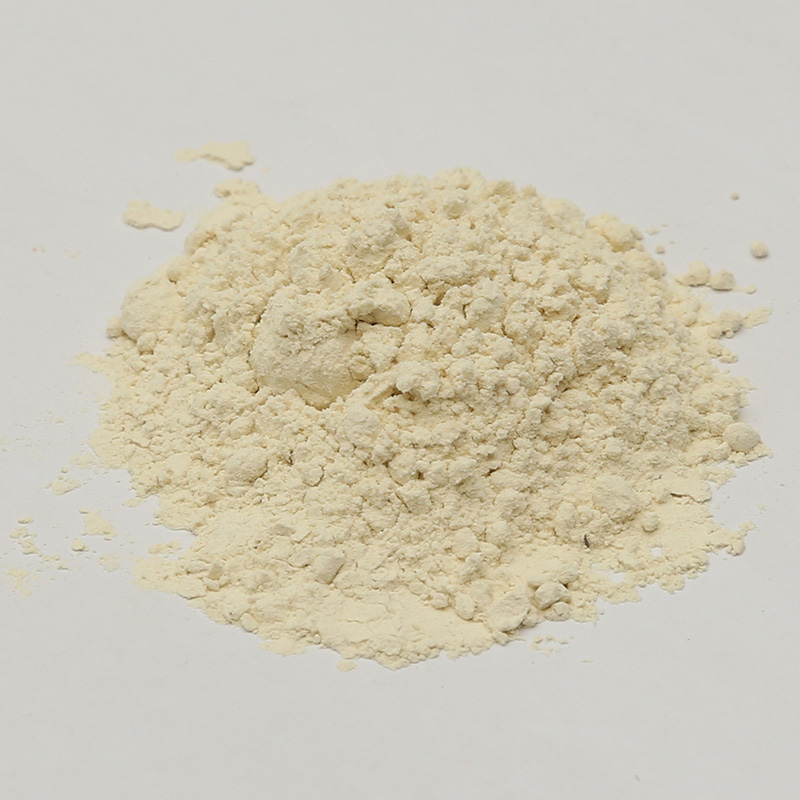

Many types of rubber accelerators are hygroscopic, meaning they readily absorb water from the environment. Moisture exposure can initiate hydrolytic reactions, reducing the concentration of active compounds and altering chemical composition. Even minimal water uptake may cause clumping or caking, which complicates measurement, handling, and mixing in the rubber compounding process. Over time, this can result in slower curing rates, inconsistent cross-linking, and diminished mechanical properties in the final rubber product. Therefore, controlling humidity levels is crucial to prevent these adverse effects.

Temperature and Environmental Factors

In addition to moisture, temperature plays a key role in the stability of rubber accelerators during storage. High temperatures can accelerate chemical degradation or trigger unwanted reactions, decreasing effectiveness. Conversely, very low temperatures can cause crystallization, aggregation, or separation in some formulations, affecting the uniformity of the additive. Proper storage involves maintaining stable, moderate temperatures to prevent thermal stress and protect the chemical integrity of the accelerator. Well-ventilated storage areas can also reduce the risk of localized heat buildup or condensation that might contribute to degradation.

Packaging and Protective Measures

The choice of packaging is a critical factor in preventing moisture-induced degradation of Rubber Accelerator. Airtight, moisture-resistant containers such as polyethylene drums, laminated bags, or sealed metal tins effectively minimize exposure to humidity. Incorporating desiccants or moisture-absorbing packets within the packaging further enhances protection against water ingress. Clear labeling that indicates storage instructions, shelf life, and handling precautions ensures that personnel follow practices, reducing the risk of accidental degradation during routine use or transportation.

Handling Practices and Shelf Life Management

Even with high-quality packaging, proper handling is essential for maintaining stability. Minimizing the duration containers remain open and using clean, dry tools for transfer reduces exposure to environmental moisture and contamination. Regularly inspecting stored accelerators for signs of caking, clumping, or discoloration helps identify compromised material early. Following manufacturer-recommended shelf life and storage guidelines ensures that the Rubber Accelerator retains its full activity for its intended period of use, maintaining reliable vulcanization performance.

Ensuring Long-Term Stability

Rubber Accelerator can be sensitive to moisture and environmental factors during storage, which may compromise its chemical activity and reduce vulcanization efficiency. Proper management of storage conditions, including moisture control, temperature stability, suitable packaging, and careful handling, is essential for maintaining long-term stability. By following recommended guidelines and implementing protective measures, manufacturers and users can ensure that the accelerator remains effective, providing consistent performance, improving production efficiency, and maintaining the quality of rubber products. Awareness of these storage sensitivities helps reduce waste, optimize operational reliability, and extend the useful life of the chemical.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体