| Location: | China |

| Business Type: | Manufacturer, Exporter |

| Brands: | Donghai & OEM |

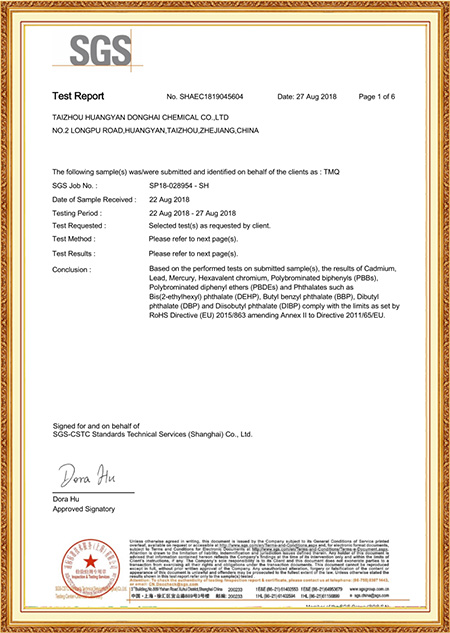

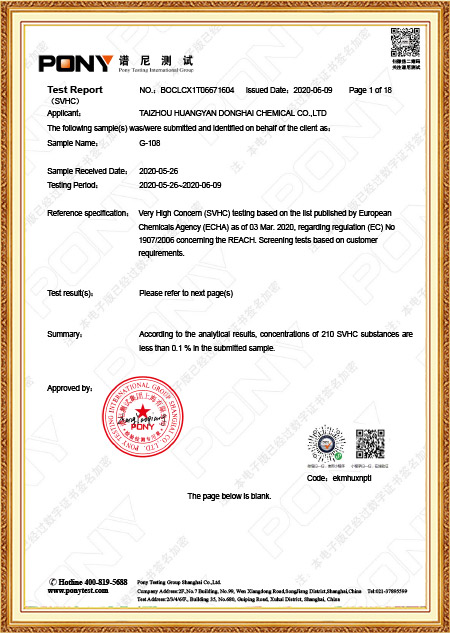

| Certificate: | ISO14001:2015, ISO9001:2015 |

| Price: | Consultation |

| Packing details: | Bag |

| Delivery time: | 10~25days |

| Payment method: | TT |

Chemical name: N,N'-m-phenylene bismaleime

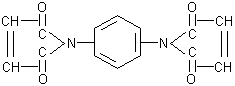

Structural formula:

Molecular formula: C14H8N2O4

Molecular weight: 268.2

CAS NO.: 3006-93-7

EINECS No 221-112-8

Quality standard:

|

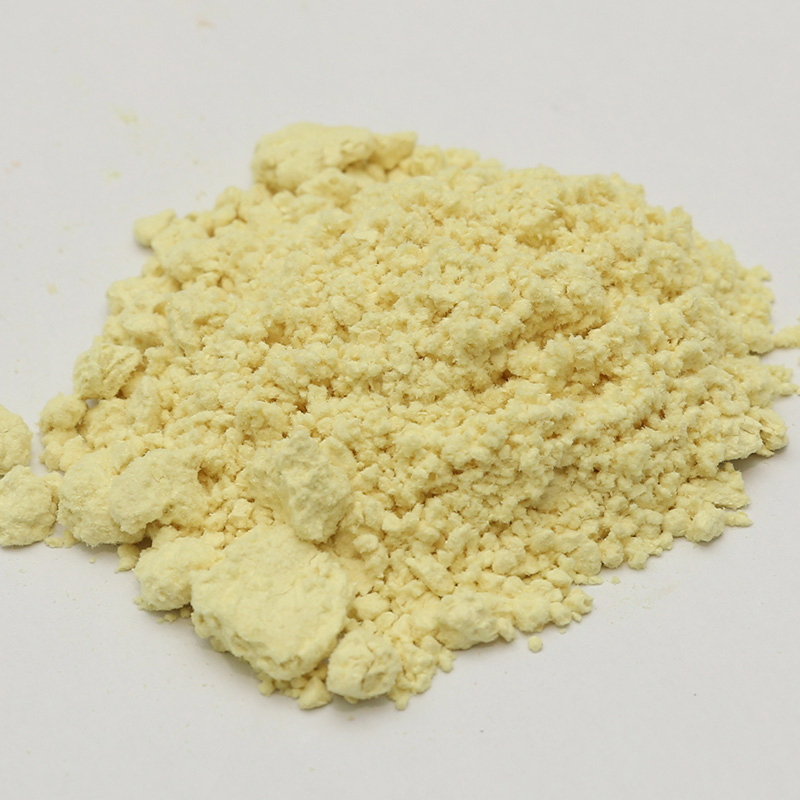

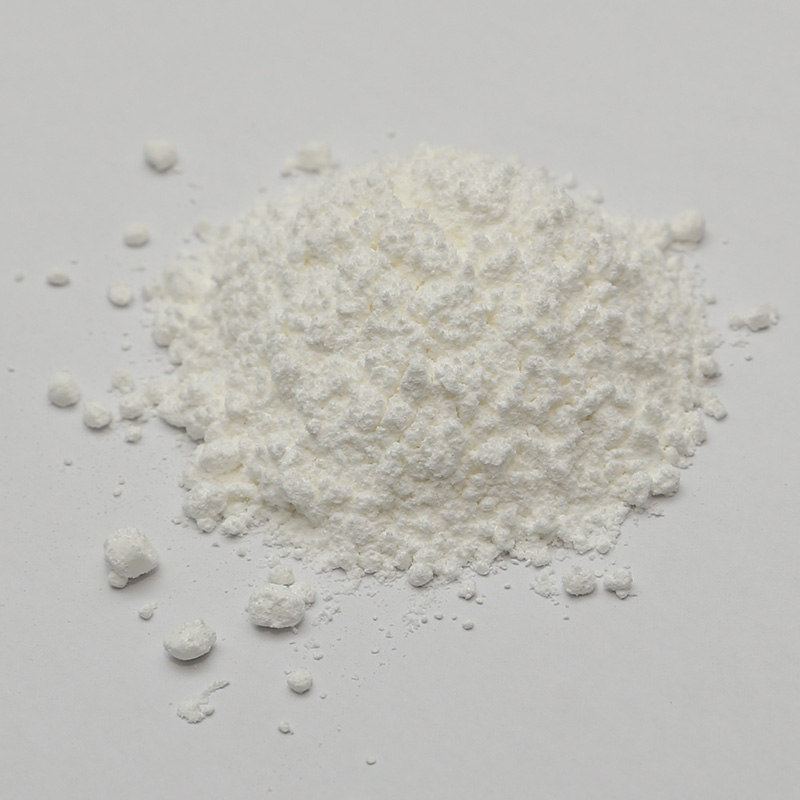

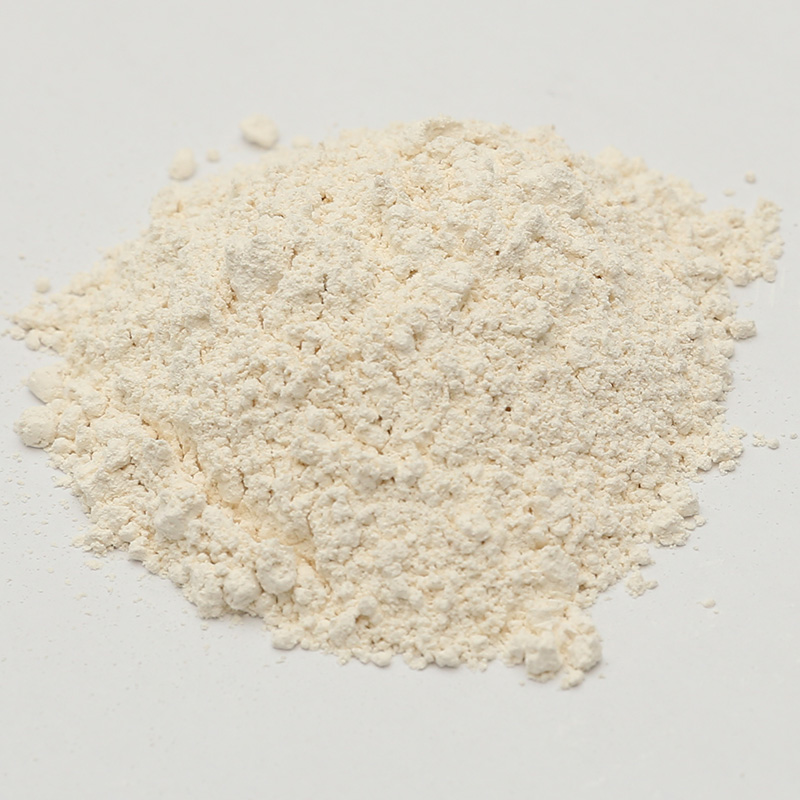

Appearance |

yellow or brown powder |

|

Loss on heat% |

≤ 0.5(70°C /2h) |

|

Ash % |

≤ 0.5 |

|

Melting point |

≥ 195°C |

Properties:

Yellow or brown powder, specific gravity: 1.44, soluble in tetrahydrofuran and heat propanone, insoluble in petroleum ether, chloroform, benzene and water, melting point: higher than 195°C.

Uses:

Being a kind of multifunctional rubber additive HVA-2 could be used as vulcanizing agent in regular rubbers, act as the cocuring agent for peroxide system. It is also coud be act as antiscorching agent or tackfying agent. Cooperating with sulfur in nature rubber HVA-2 could prevent reversing, improving rubber’s resistance to thermal, reducing pyrogenesis,increase the bond force between rubber and cord. It could desolve the shoulder’s seperation effectively when HVA-2 applicated in lorry tires’s shoulder or buffering layer.When used as cocuring agent in Chlorosulfonated polyethylene rubber(CR), styrene-butadiene rubber(SBR), Nitrile rubber(NBR), isoprene rubber(IR), Butyl rubber(IIR), Bromobutyl rubber, acrylic rubber(ACM), Silicon rubber(SI) and other rubbers, HVA-2 can improve the polymer’s correlation performance and heat resistance effectively. HVA-2 could be applicated in the high-temperature vulcanization system and reducing permanent set effectively ,save the peroxide agen’s dosage ,preventing scorching during the vulcanizing process, improving the bond force between rubber and the frame.As a non-sulfur vulcanizing agent when used in cable polymers, HVA-2 can substitute of sulfurized vulcanizing agentsuch as thiazole type, thiuram and other, which solve the blackening which cause by copper’s pollution.

Dosage:

0.5-1.0 portion when used as antiscorching agent, 2-3 portion when used as vulcanizing agent, 1.5 portion when used as compression deformation improving agent, 0.5-5.0 portion when used as adhesion strength improving agent.

Packing:

composite bag, Net wt. 20kg

English

English Português

Português Español

Español русский

русский 中文简体

中文简体