China Wholesale Vulcanizing Materials Liquid Vulcanized Rubber Agent Factory

The rubber industry has been at the forefront of material science, constantly evolving to meet the demands of various sectors, from automotive to aerospace. A key component in the production of high-performance rubber is the Vulcanizing Agent. These agents are responsible for the cross-linking of rubber polymers, which is essential for enhancing the material's strength, elasticity, and resistance to heat and chemicals. As technology advances, so do the innovations in it, resulting in the development of advanced rubber applications. This article will explore the innovations in China Vulcanizing Agents and their impact on the future of rubber production.

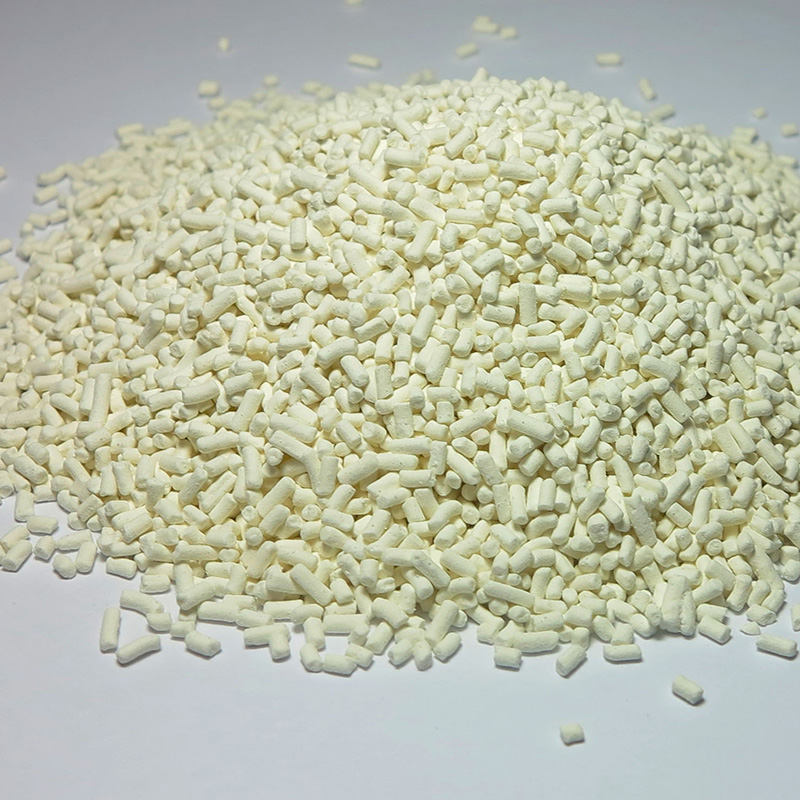

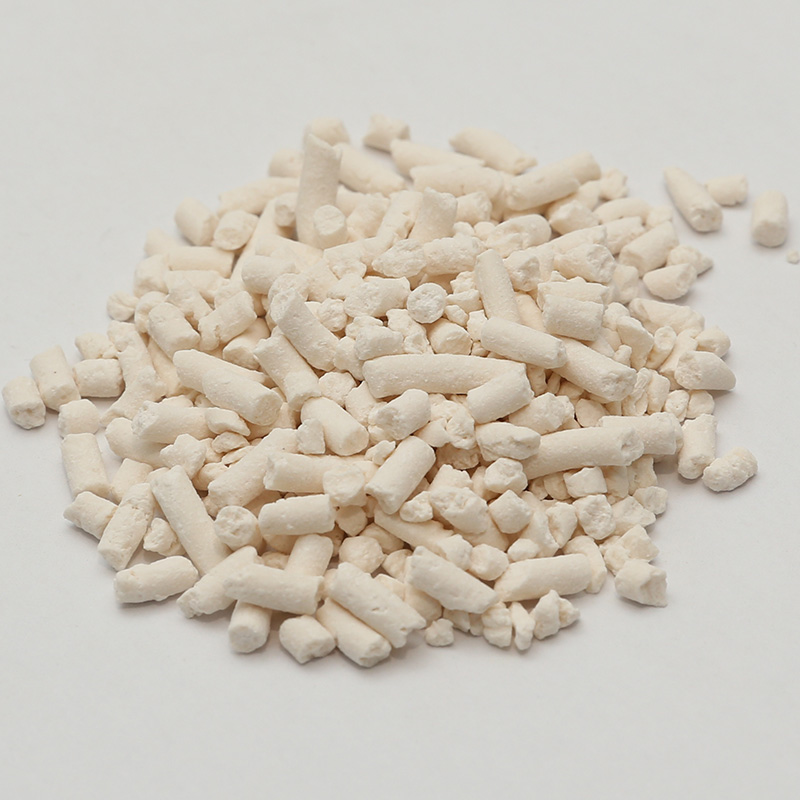

Vulcanizing Agents are chemical compounds that facilitate the vulcanization process, which is the transformation of raw rubber into a more stable and durable material. The process involves the formation of cross-links between polymer chains, which significantly improves the rubber's physical properties. Traditional ones, such as sulfur, have been used for centuries, but modern advancements have led to the development of new agents that offer improved performance and environmental benefits.

One of the significant innovations in Vulcanizing Agents is the use of peroxide curing systems. These agents offer a sulfur-free alternative, which is particularly beneficial for applications where sulfur can cause corrosion or staining. Peroxide curing systems also result in fewer by-products, making them more environmentally friendly and suitable for producing rubber goods that come into contact with food or pharmaceuticals.

The development of high-performance Vulcanizing Agents has allowed for the creation of rubber products with exceptional resistance to heat, chemicals, and wear. These agents are crucial in industries where rubber components are subjected to severe conditions, such as in the automotive and aerospace sectors. The use of these advanced agents can significantly extend the lifespan of rubber parts and reduce maintenance costs.

Sustainability has become a key focus in the rubber industry, resulting in the research and development of bio-based Vulcanizing Agents. These agents are derived from renewable resources and are designed to reduce the environmental impact of rubber production. The use of bio-based agents not only contributes to a greener manufacturing process but also offers potential performance benefits, such as improved processability and reduced toxicity.

The integration of nanotechnology has given rise to smart Wholesale Vulcanizing Materials that can respond to specific environmental stimuli, such as temperature or pH changes. These agents can be tailored to activate at precise moments during the vulcanization process, resulting in improved control over the final properties of the rubber. Smart agents can also be designed to self-heal or change properties in response to external conditions, opening up new possibilities for adaptive rubber materials.

The innovations in Vulcanizing Agents have far-reaching implications for the rubber industry. Advanced agents enable the production of rubber goods with enhanced performance characteristics, Rubber products made with high-performance Vulcanizing Agents can withstand more wear and tear, reducing the need for frequent replacements and lowering overall costs.

In the automotive industry, the use of advanced Vulcanizing Agents can improve the safety of rubber components, such as tires and seals, by ensuring they maintain their integrity under severe conditions.

Microencapsulated Vulcanizing Agents contribute to the production of more sustainable rubber goods, aligning with the growing demand for eco-friendly products.

Smart Vulcanizing Agents allow for the creation of rubber materials with customizable properties, opening up new possibilities for tailored applications in various industries.

The continuous innovation in Liquid Vulcanized Rubber Factory is a testament to the dynamic nature of the rubber industry. As researchers and manufacturers push the boundaries of what is possible, the use of advanced it is becoming increasingly prevalent. These agents not only improve the performance and safety of rubber products but also contribute to more sustainable and efficient production processes. The future of rubber production is undoubtedly tied to the ongoing advancements in Vulcanizing Agents, which will continue to shape the industry's trajectory toward higher performance and environmental responsibility.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体