China Cheap Rubber Gum Vulcanizing Glue Agent Company

In the quest for sustainable development, the rubber industry has been seeking environmentally friendly solutions to reduce its environmental footprint. A critical component in this endeavor is the Vulcanizing Agent, which plays a pivotal role in the cross-linking process of rubber polymers. This article delves into the impact of China Vulcanizing Agents on the development of eco-friendly rubber products and explores how innovations in this area can contribute to a greener future.

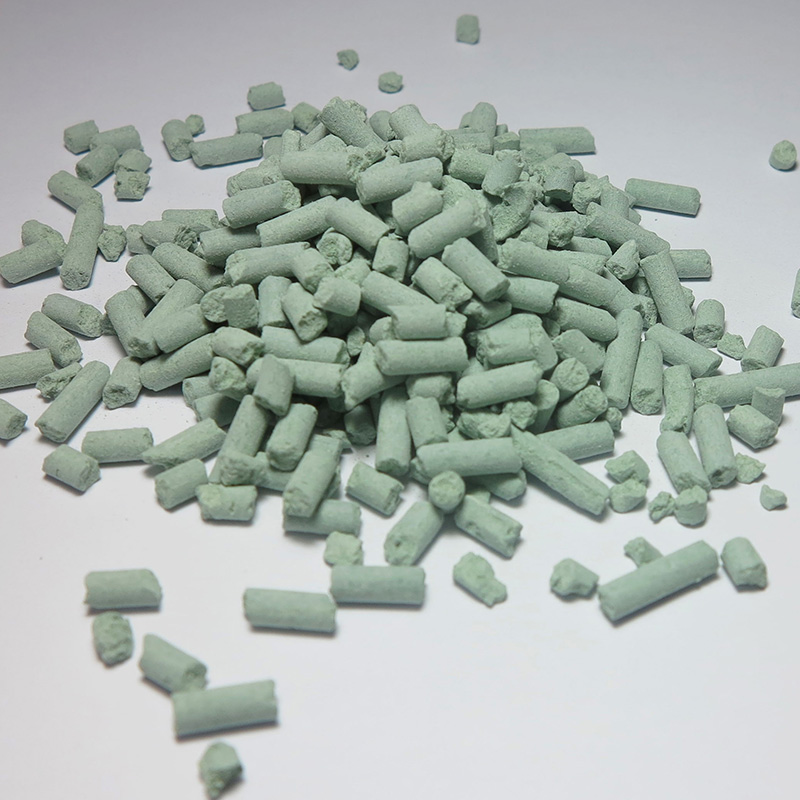

Vulcanizing Agents are essential in the rubber industry as they facilitate the vulcanization process, which involves the cross-linking of rubber molecules to improve the material's strength, elasticity, and durability. Traditional Vulcanizing Agents, such as sulfur and certain accelerators, have been the industry standard for decades. However, with growing environmental concerns, there is a need to reevaluate the use of these agents and explore alternatives that are less harmful to the environment.

Traditional Vulcanizing Agents have been linked to various environmental issues. Sulfur, for instance, can release sulfur dioxide during the vulcanization process, contributing to air pollution. Additionally, some accelerators used in conjunction with sulfur can result in the formation of harmful by-products, posing risks to both human health and the environment. The rubber industry's reliance on these agents has prompted a search for more sustainable alternatives.

The demand for environmentally friendly rubber solutions has driven the development of innovative Cheap Rubber Vulcanizing Glues. These new agents are designed to reduce environmental impact while maintaining the performance characteristics required for various applications.

Peroxides have emerged as a viable alternative to sulfur, offering a cleaner vulcanization process with fewer harmful by-products. They are particularly useful in the production of rubber goods that require high purity and resistance to heat and chemicals.

The development of bio-based Vulcanizing Agents from renewable resources is gaining traction. These agents are derived from natural sources, such as vegetable oils and resins, and are biodegradable, reducing their environmental impact.

Advanced Vulcanizing Agents are being engineered to provide performance without compromising environmental sustainability. These agents can offer improved resistance to wear, tear, and environmental stressors, making them suitable for high-performance applications.

The transition from traditional to eco-friendly Vulcanizing Agents is not without challenges. The rubber industry must balance the need for performance with environmental considerations.

Continued investment in R&D is crucial to developing Vulcanizing Agents that meet the performance standards of traditional agents while reducing their environmental impact.

As new Vulcanizing Agents are developed, they must be tested and approved to ensure they comply with international environmental and safety standards.

The adoption of eco-friendly Vulcanizing Agents requires a robust supply chain that can source and distribute these agents efficiently and sustainably.

As the rubber industry moves towards more sustainable practices, the development of environmentally friendly Vulcanizing Rubber Gum Company is becoming increasingly important. The future of these agents lies in innovation, with a focus on reducing the environmental impact of rubber production while maintaining the performance characteristics that make rubber a versatile and essential material.

The impact of Vulcanizing Agents on environmentally friendly rubber solutions is significant. As the industry continues to innovate and develop new agents, the potential for a greener, more sustainable future in rubber production becomes more attainable. By embracing eco-friendly Vulcanizing Agents, the rubber industry can contribute to global efforts to reduce environmental pollution and promote sustainable development. The challenge now is to accelerate the adoption of these agents and ensure that they become the new standard in rubber production worldwide.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体