In everyday life, rubber products are all around us—from car tires and shoe soles to industrial belts and household items. To keep these products in good condition for as long as possible, manufacturers rely on special additives during the production process. One of these important additives is the rubber antioxidant agent. Though it might not be a term many people hear often, it plays a big role in how rubber products stay durable and reliable over time. Let’s take a closer look at what a rubber antioxidant agent is and how it works in rubber processing.

A rubber antioxidant agent is a chemical additive used during the production of rubber products to help them resist damage from oxygen, heat, ozone, and other environmental factors. Without it, rubber tends to harden, crack, or lose flexibility when exposed to air and sunlight over time. This is why adding an antioxidant agent is an essential part of rubber processing, especially for products designed for outdoor or high-stress applications.

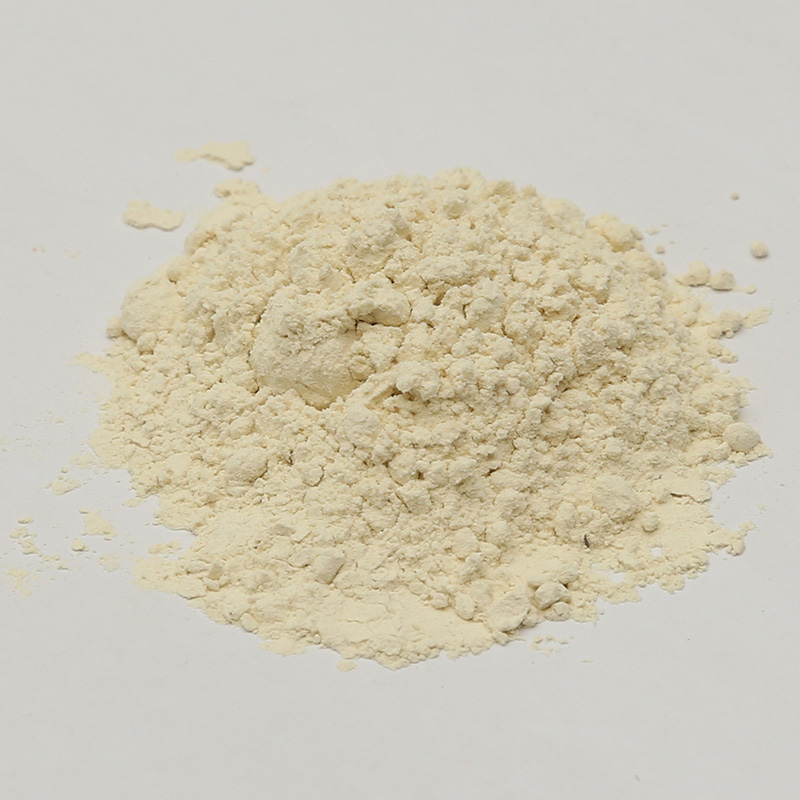

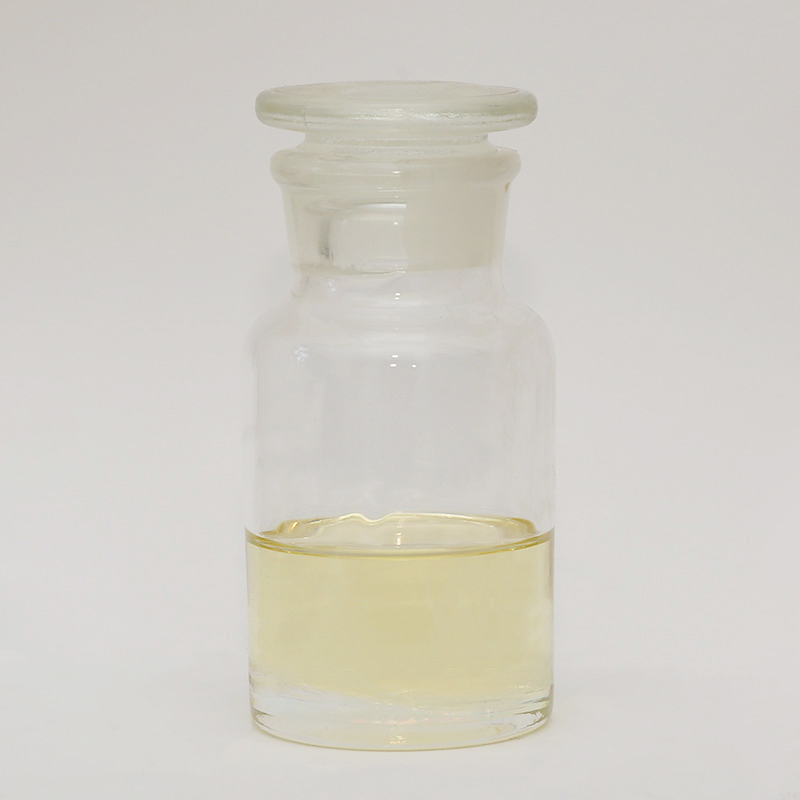

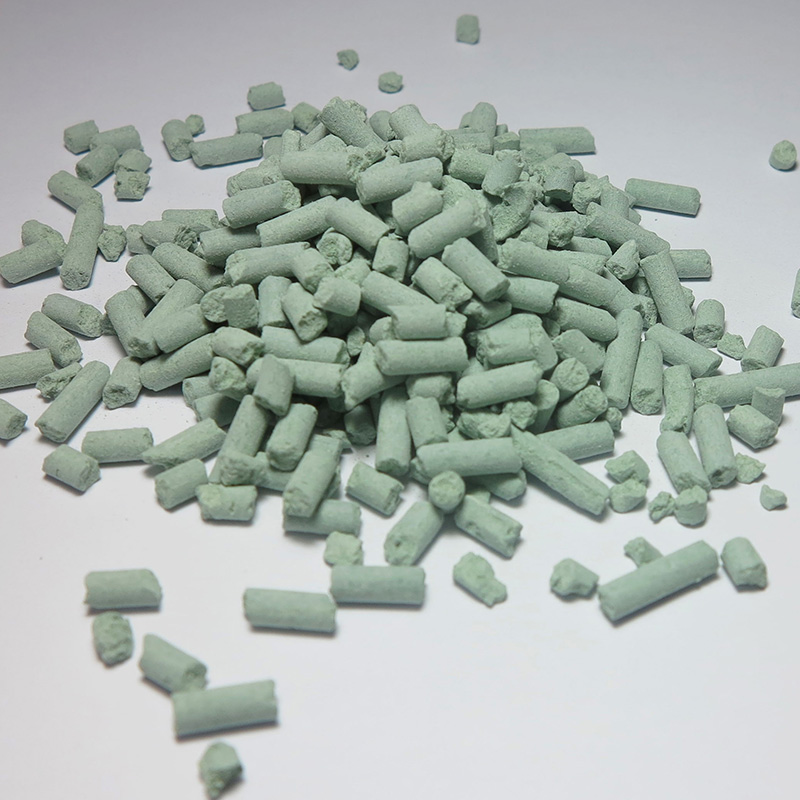

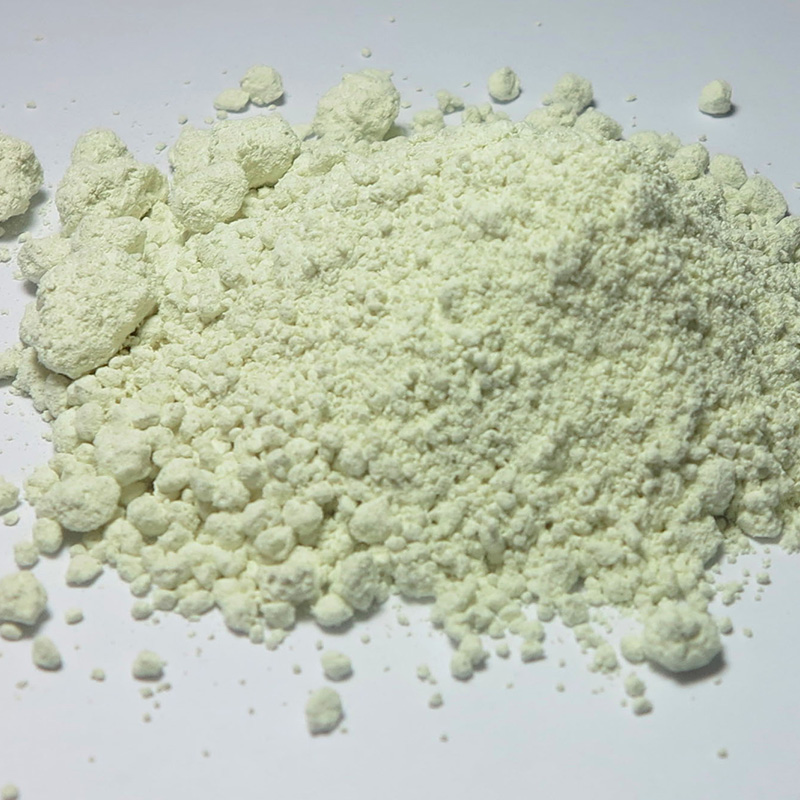

There are different types of rubber antioxidant agent options available, depending on the type of rubber being produced and the conditions the final product will face. Each type works a little differently, but they all share the common goal of protecting the rubber material from premature aging.

The way a rubber antioxidant agent works is fairly straightforward. When rubber is exposed to heat, air, or light, a chemical reaction known as oxidation can start. This reaction breaks down the rubber’s molecular structure, causing it to become brittle, discolored, or cracked.

A rubber antioxidant agent helps slow down this process by neutralizing the free radicals that form during oxidation. These free radicals are unstable molecules that damage rubber’s long-chain structure. By stopping them early, the antioxidant agent helps maintain the rubber’s elasticity, color, and strength.

Some types of antioxidant agent are also designed to block ozone, which is a gas that can quickly crack and weaken rubber surfaces, especially in tires and outdoor products. Other agents work better at high temperatures, protecting products like industrial seals and hoses that are constantly exposed to heat.

Why Rubber Products Need a Rubber Antioxidant Agent

Rubber materials naturally react to their environment. Whether it’s a pair of running shoes or a conveyor belt in a factory, rubber tends to age when exposed to oxygen, sunlight, or heat for long periods. This can result in hardening, surface cracks, or even breakage.

By adding a rubber antioxidant agent, manufacturers can extend the usable life of these products and improve their overall performance. It ensures that rubber items stay flexible, durable, and safe to use, even after years of exposure to the elements. For industries like automotive, construction, and consumer goods, this makes a big difference in product quality and customer satisfaction.

You’ll find a rubber antioxidant agent in nearly every type of rubber product, whether natural or synthetic. Some everyday examples include:

Car tires: To prevent cracking and maintain grip performance.

Shoe soles: To keep them from hardening and breaking down.

Industrial belts and hoses: To handle continuous heat and chemical exposure.

Rubber seals and gaskets: To maintain their shape and seal over time.

Electrical insulation: To keep it flexible and safe in different environments.

Even in small products like rubber bands or kitchen gloves, an antioxidant agent helps maintain the item’s usability and appearance.

A rubber antioxidant agent might be a behind-the-scenes player in the rubber industry, but it’s a key part of keeping rubber products reliable, safe, and long-lasting. By protecting against oxidation and environmental damage, this additive ensures that everything from vehicle tires to industrial hoses can perform as expected. Understanding how a rubber antioxidant agent works helps explain why so many of the rubber items we use every day stay in good condition despite constant wear and exposure.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体