Rubber additives play a crucial role in enhancing the performance and properties of rubber materials used in various industries. These additives are incorporated into rubber compounds during the manufacturing process to improve qualities such as durability, flexibility, strength, and resistance to environmental factors. There are many types of Custom Rubber Additives, each designed to serve specific functions depending on the intended application. In this article, we will explore the different types of Rubber Additives and their common applications in the industry.

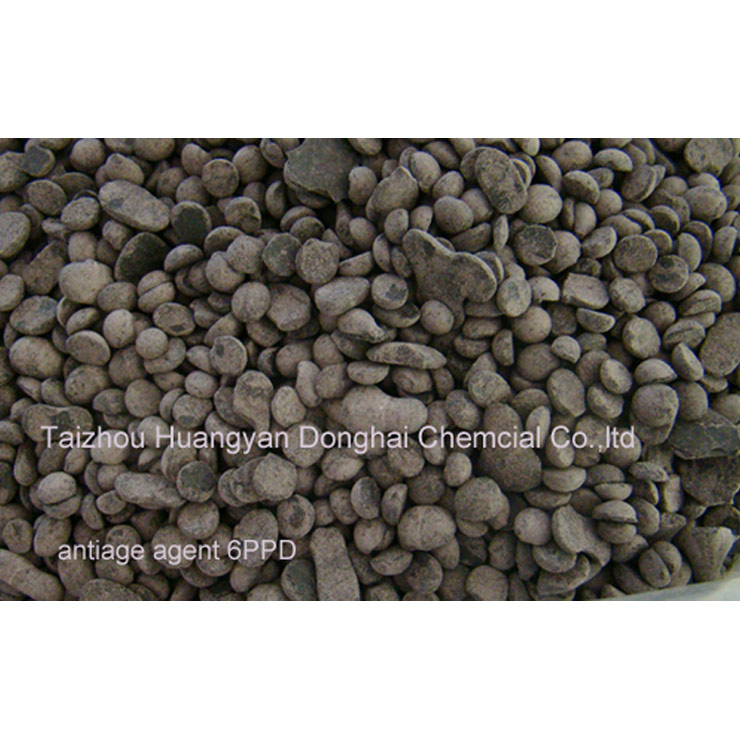

Antioxidants and antiozonants are essential Masterbatch Rubber Prices used to protect rubber products from the damaging effects of oxidation and ozone exposure. Over time, rubber materials exposed to air and sunlight can degrade, resulting in cracks, brittleness, and reduced performance. Antioxidants work by neutralizing free radicals, which are responsible for causing oxidation. Antiozonants, on the other hand, provide protection against the harmful effects of ozone, which can result in surface cracking.

Plasticizers are another type of Rubber Additives that help enhance the workability and flexibility of rubber materials. These additives reduce the viscosity of the rubber compound, making it easier to process during manufacturing. To improve the flexibility and softness of rubber, plasticizers are commonly used in applications where the material needs to remain pliable, such as in the production of footwear, seals, gaskets, and hoses.

Fillers are substances added to rubber compounds to enhance specific properties, such as strength, hardness, and wear resistance. Common fillers include carbon black, silica, clay, and talc. These fillers improve the rubber's physical properties, including abrasion resistance, tensile strength, and heat stability.

Curing agents, also known as vulcanizing agents, are critical Rubber Additives used to initiate the crosslinking process in rubber. This chemical process, known as vulcanization, enhances the rubber’s elasticity, strength, and heat resistance. Common curing agents include sulfur, peroxides, and other chemical compounds.

The vulcanization process is essential for improving the overall performance of rubber products, especially in applications that require high tensile strength and resistance to heat. For example, rubber products used in automotive engines or machinery parts rely heavily on effective vulcanization to ensure durability and resistance to high temperatures.

By improving the fire resistance of rubber materials, flame retardants help ensure that rubber products perform safely in environments with elevated risks of fire. These additives work by either inhibiting the ignition process or slowing down the spread of flames, thus reducing the potential damage caused by fires.

Accelerators are Cheap Vulcanizing Rubber Products used to speed up the vulcanization process, allowing manufacturers to reduce production times. These chemicals help to activate curing agents, making the rubber cure faster and more efficiently. Accelerators are essential for optimizing the manufacturing process, ensuring that rubber products are produced at a consistent rate without compromising on quality.

Stabilizers are Rubber Additives used to improve the long-term stability of rubber materials. They help protect the rubber from degradation due to heat, light, and oxidation. Stabilizers are essential in applications where rubber products are exposed to harsh environmental conditions over an extended period.

Rubber Additives play a vital role in enhancing the performance, quality, and durability of rubber materials used in a wide range of industries. From improving the flexibility and workability of rubber to increasing its resistance to oxidation and fire, each type of Rubber Additive serves a unique function. By understanding the different types of additives available and their applications, manufacturers can select the right formulations to meet the specific needs of their products, resulting in higher efficiency, reduced costs, and improved product performance. Whether it's for the automotive, construction, or medical industries, Rubber Additives are an essential part of creating high-quality rubber products.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体