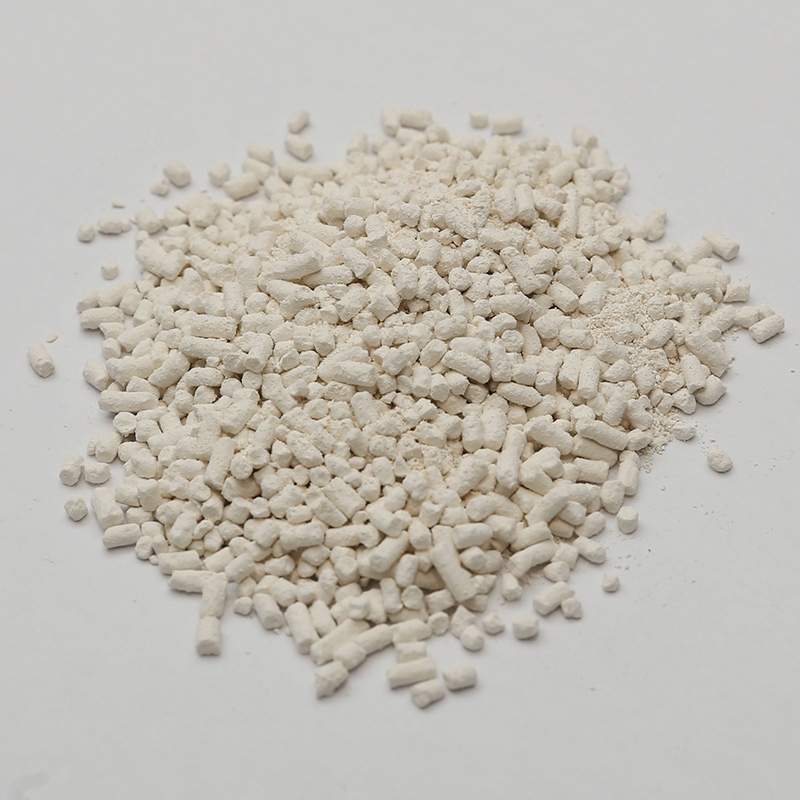

Sale Cheap Rubber Tackifying Resins in China

Rubber Tackifying Resins are a class of polymers that play a pivotal role in the rubber industry, enhancing the adhesive properties and overall performance of rubber compounds. These resins are known for their ability to improve the tackiness, adhesion, and cohesion of rubber, making them indispensable in various applications. This article delves into the science behind the Sale Rubber Tackifying Resins, exploring their composition, properties, and applications in the rubber industry.

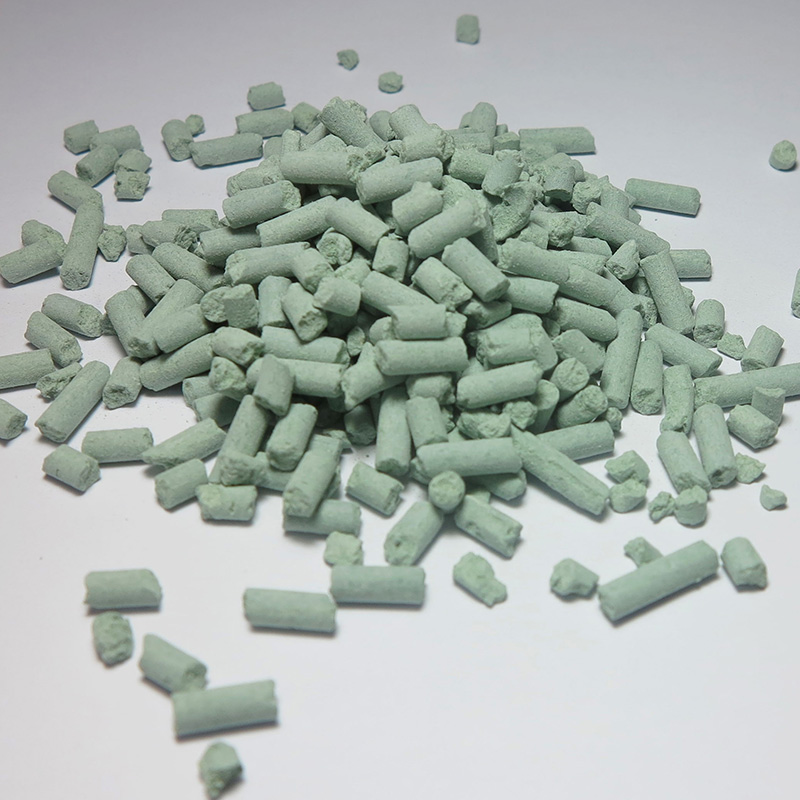

Rubber Tackifying Resins are typically derived from natural or synthetic sources and are composed of complex hydrocarbon molecules. They are often classified into two main categories: natural tackifying resins and synthetic tackifying resins. Natural tackifying resins, such as rosin and its derivatives, are obtained from plant sources, while synthetic tackifying resins are produced through chemical processes. Both types contribute to the tackiness of rubber compounds, but they differ in their chemical structures and properties.

The unique properties of Rubber Tackifying Resins are what makes them so valuable in the rubber industry. They possess high tack and adhesion, which are essential for creating strong bonds between rubber and various substrates. Additionally, these resins can improve the processability of rubber compounds, making them easier to mix and mold. The compatibility of Rubber Tackifying Resins with different rubber types is another crucial factor, as it allows for their use in a wide range of applications.

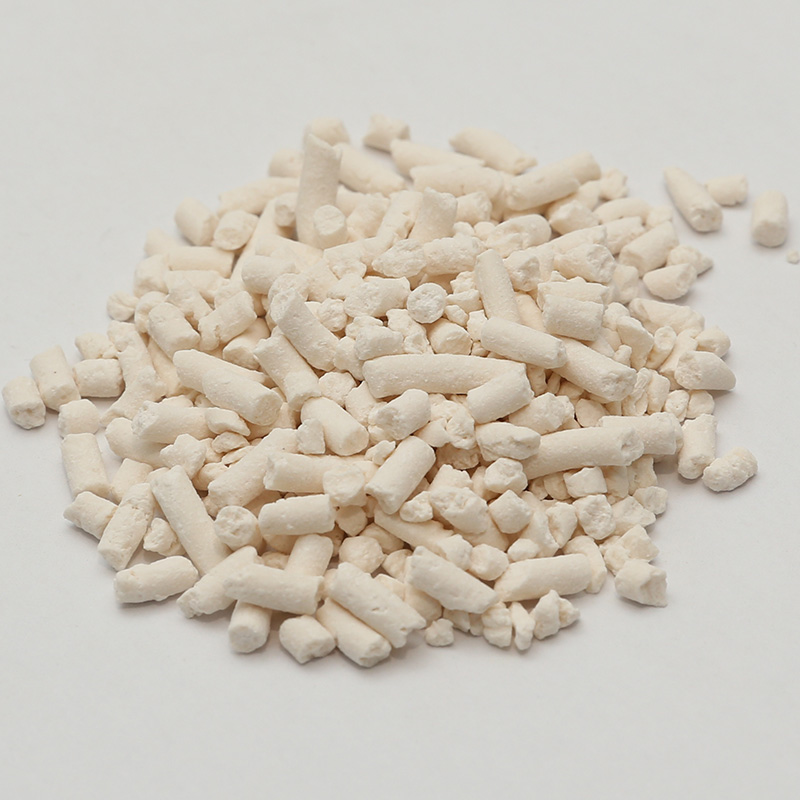

The versatility of Rubber Tackifying Resins is evident in their numerous applications across various industries. In the tire manufacturing sector, they are used to enhance the adhesion between rubber layers, improving the tire's durability and performance. In the adhesives industry, Cheap Tackifying Resins are incorporated into formulations to create strong, flexible bonds that can withstand various environmental conditions. They are also used in the production of pressure-sensitive adhesives, such as those found in labels and tapes, where their tackiness is a key attribute.

Rubber Tackifying Resins are often added to rubber compounds to modify their physical properties. They can increase the tackiness of the rubber, which is beneficial for applications requiring strong adhesion, such as in the automotive and construction industries. The addition of rubber viscosifying resin can also improve the heat resistance, oxidation resistance, and UV resistance of rubber, and extend the service life of rubber products.

The science behind the ratification process involves the interaction between rubber-tackifying resin and the rubber matrix. When these resins are mixed with rubber, they form a network of intermolecular bonds that enhance the overall tackiness of the compound. This network is responsible for the increased adhesion and cohesion properties observed in rubber compounds containing Rubber Resins in China.

As the demand for high-performance rubber products continues to grow, the role of Rubber Tackifying Resins in the industry is expected to expand. Researchers are continuously exploring new ways to improve the properties of these resins, such as developing more sustainable and environmentally friendly options. The future of Rubber Tackifying Resins lies in their ability to meet the evolving needs of the rubber industry while maintaining their core function of enhancing tack and adhesion.

Rubber Tackifying Resins are a critical component in the rubber industry, offering a range of benefits that enhance the performance and quality of rubber products. Their unique properties, derived from both natural and synthetic sources, make them an essential ingredient in the formulation of rubber compounds. As the science behind Rubber Tackifying Resins continues to advance, their role in the production of high-quality rubber goods will only become more significant, ensuring their place as a key player in the future of the rubber industry.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体