Rubber is a versatile material used across various industries, from automotive to healthcare, due to its properties, such as elasticity, durability, and resilience. However, rubber in its natural form may not always meet the specific requirements of certain applications. This is where Rubber Additives come into play. These chemical compounds are incorporated into rubber during the manufacturing process to enhance or modify the material's inherent properties, making it suitable for specialized uses. In this article, we will explore the science behind China Rubber Additives and how they impact the properties of rubber materials.

Rubber Additives are substances added to rubber compounds to modify their physical, chemical, and mechanical properties. They are typically used during the compounding stage, where various raw materials are combined to create a specific rubber formulation. These additives work by altering the behavior of the rubber, improving its performance under various conditions. Common Rubber Additives include antioxidants, plasticizers, curing agents, stabilizers, fillers, and accelerators, each serving a different purpose in the rubber production process.

Rubber Additives primarily function by altering the molecular structure or the interaction between molecules within the rubber compound. For example, curing agents, also known as vulcanizing agents, facilitate a chemical reaction that crosslinks the rubber molecules, which enhances the material's elasticity and strength. Similarly, plasticizers reduce the viscosity of rubber, making it easier to process while also increasing its flexibility.

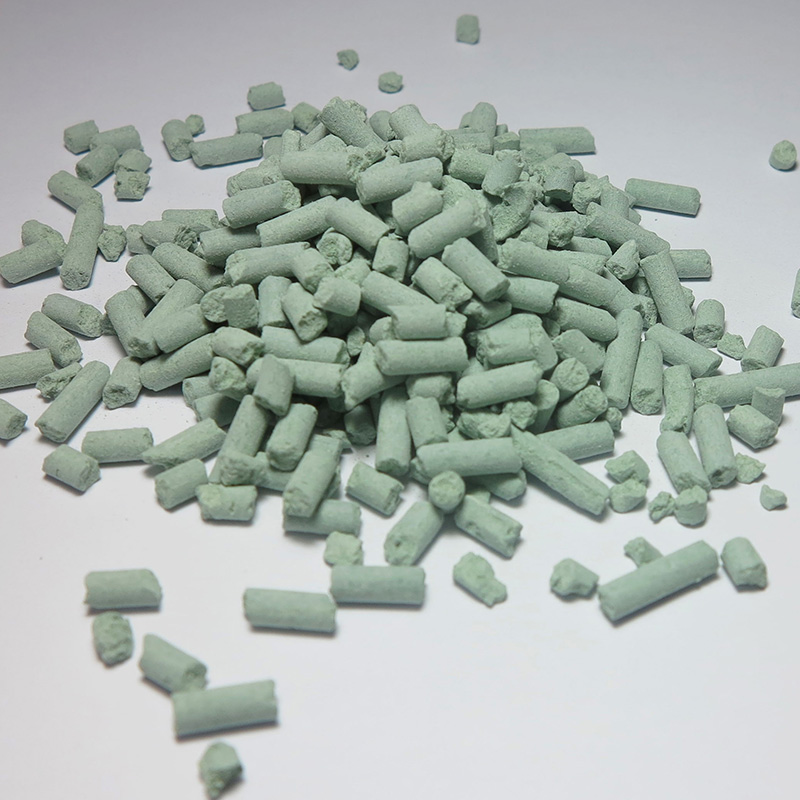

One of the important categories of Rubber Additives is antioxidants and antiozonants. These additives help protect rubber from oxidation and ozone degradation, both of which can weaken the material over time. Oxidation occurs when the rubber reacts with oxygen in the air, resulting in a breakdown of the rubber's molecular structure, which reduces its strength and flexibility. Similarly, ozone exposure can cause surface cracking and premature aging, particularly in rubber products exposed to outdoor conditions.

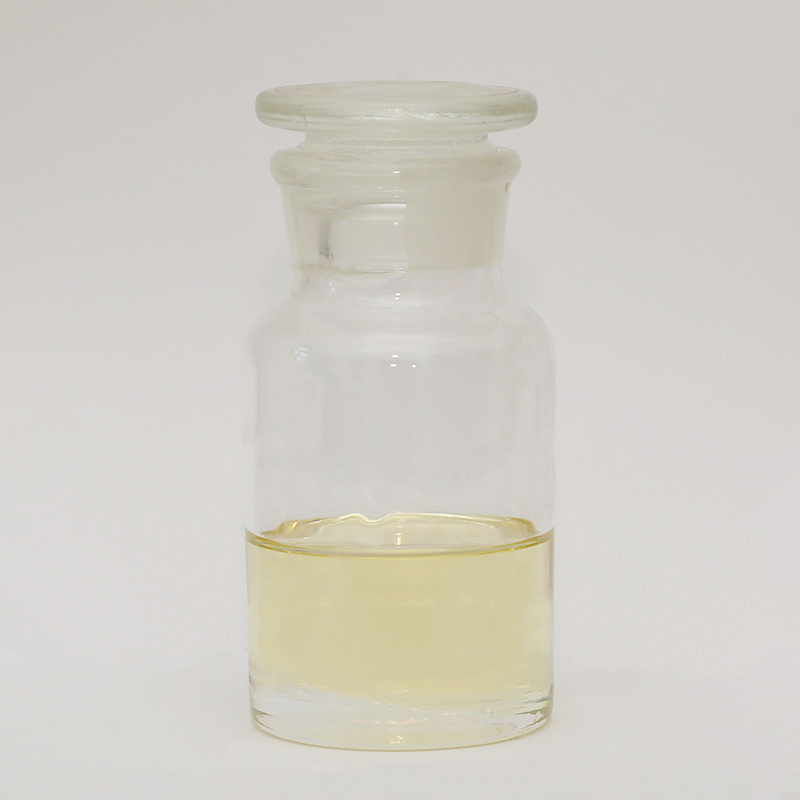

Plasticizers are another group of Rubber Additives that improve the workability and flexibility of rubber. These additives reduce the viscosity of the rubber compound, making it easier to mold or extrude into different shapes. Plasticizers act by decreasing the intermolecular forces between rubber molecules, which increases the material's pliability. This is especially useful in applications where flexibility is critical, such as in the production of gaskets, seals, and footwear.

However, the use of plasticizers must be carefully controlled, as excessive amounts can reduce the rubber's mechanical properties, such as its tensile strength and wear resistance. Therefore, finding the balance of plasticizer concentration is essential for achieving the desired combination of flexibility and durability.

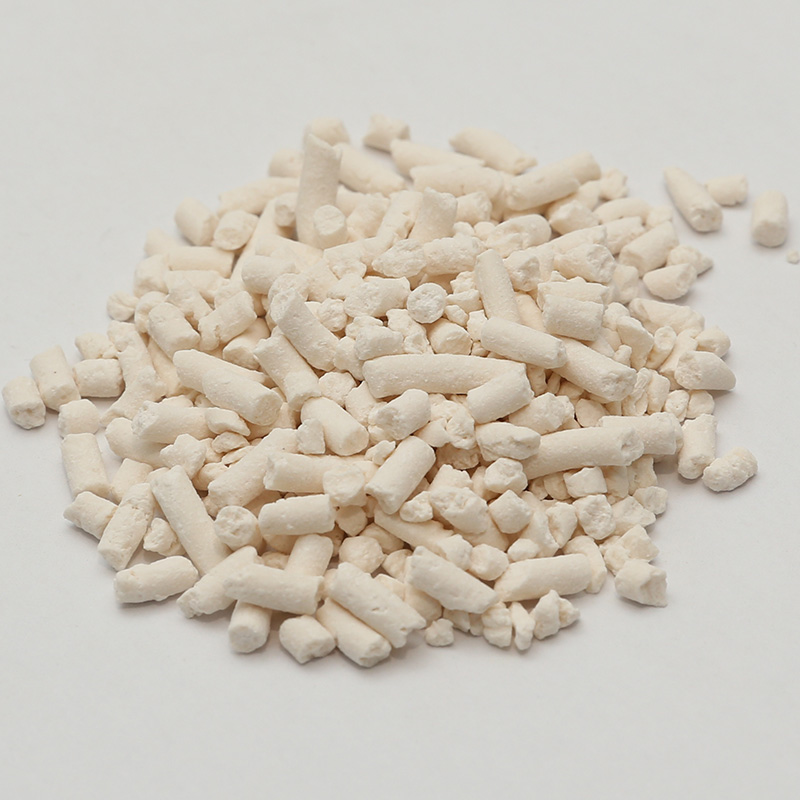

Curing agents are essential Custom Black Rubber Adhesives that initiate the process of vulcanization, which involves the chemical crosslinking of rubber molecules. This process enhances the rubber's elasticity, strength, and heat resistance. Without curing agents, rubber would remain in its uncrosslinked state, which would prevent it from achieving the high-performance properties required for applications.

Stabilizers are another critical category of Rubber Additives, particularly in applications where rubber products are exposed to harsh environmental conditions. These additives work by preventing or slowing down the degradation of rubber caused by factors such as heat, light, and chemicals. Stabilizers can protect rubber from thermal degradation during processing and help maintain its properties over time.

Rubber Additives play a significant role in modifying the properties of rubber materials to meet the specific requirements of various applications. Whether it's enhancing durability with antioxidants, improving flexibility with plasticizers, or reinforcing strength with fillers, these additives ensure that rubber products perform effectively under demanding conditions. By understanding the science behind these additives and their impact on material properties, manufacturers can optimize rubber formulations to meet the needs of industries such as automotive, healthcare, and manufacturing. The use of Vulcanizing Silicone Rubber Suppliers not only improves the material’s performance but also ensures that rubber products remain functional, reliable, and cost-effective over time.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体