Balancing Curing Efficiency and Long-Term Durability

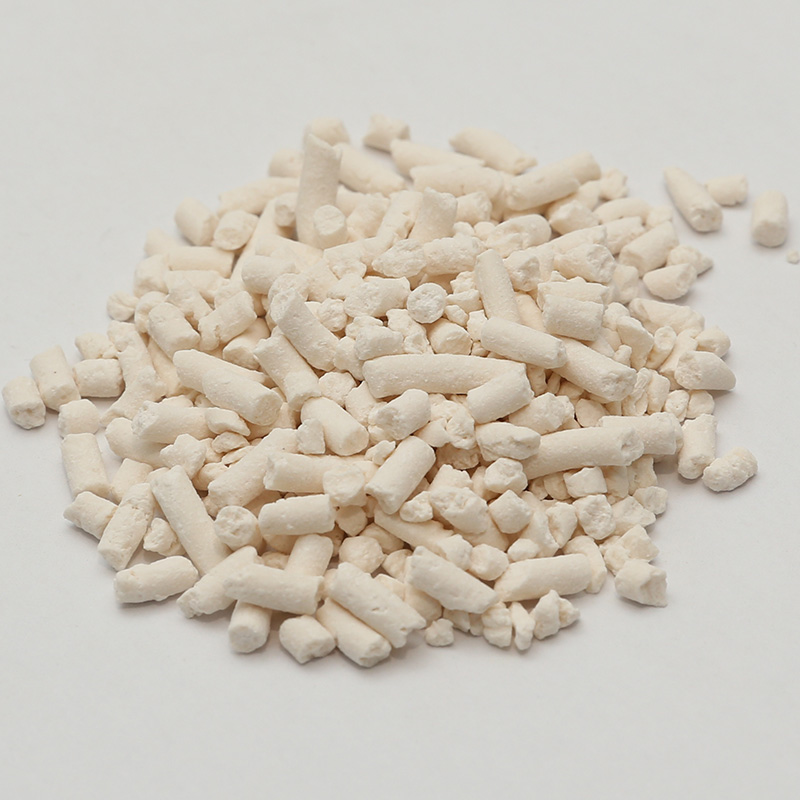

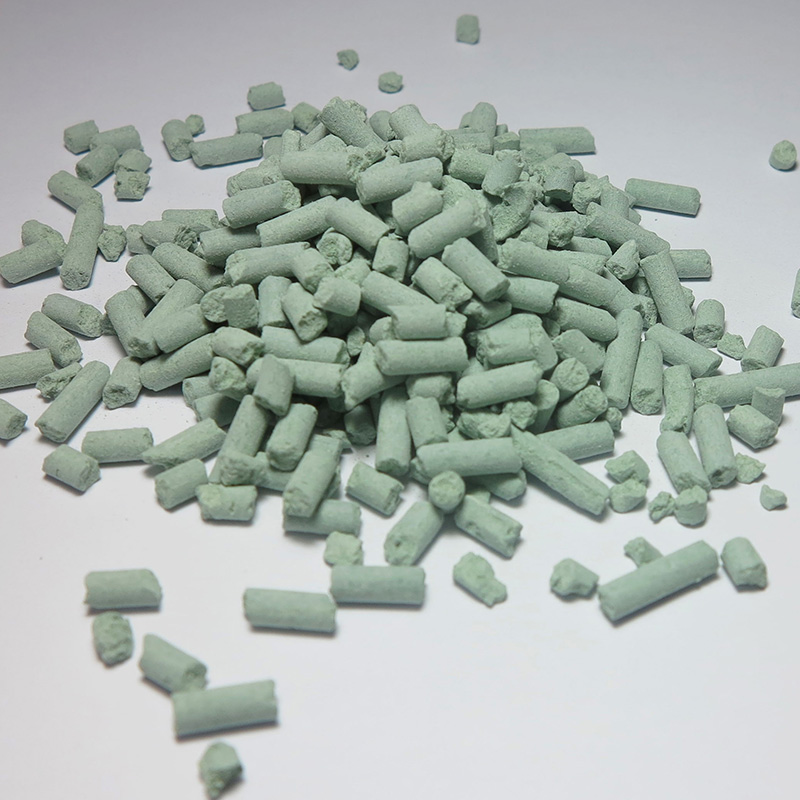

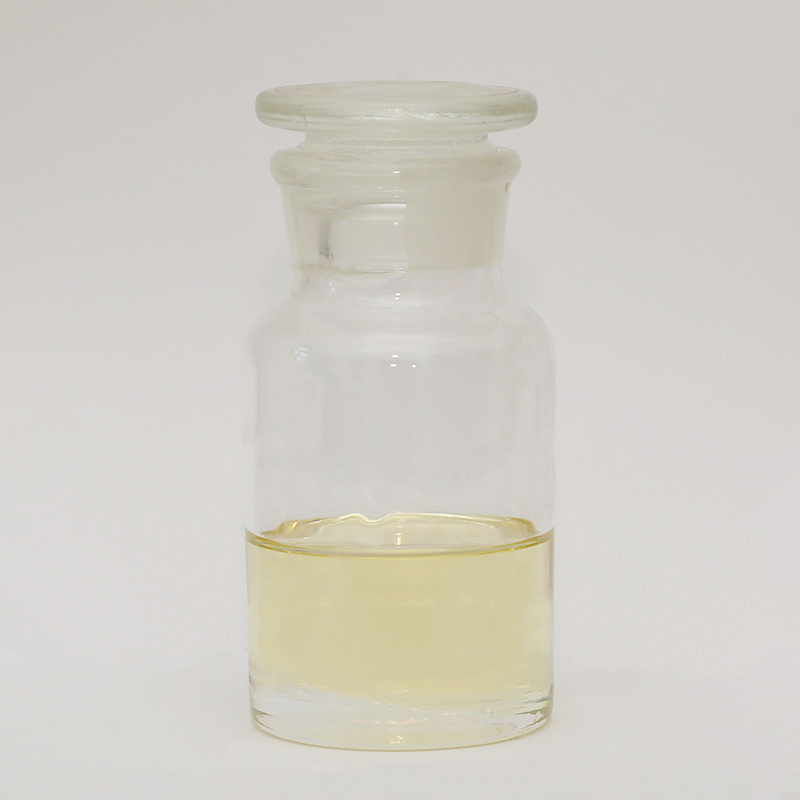

Rubber accelerators are crucial additives in the vulcanization process, enabling faster curing and improving the mechanical properties of rubber products. While their primary function is to enhance cross-linking, the choice and concentration of accelerators can also influence long-term performance characteristics, including resistance to aging and ozone. For applications exposed to environmental stress, understanding how accelerators affect durability is essential for producing high-quality, reliable rubber components.

Influence on Aging Resistance

Aging in rubber materials involves the gradual deterioration of mechanical properties due to thermal, oxidative, or chemical exposure. Rubber accelerators can affect this process indirectly by altering the cross-link density and network structure of the cured material. Accelerators that promote uniform and suitable cross-linking generally enhance the material’s thermal stability and reduce susceptibility to oxidative degradation. Conversely, excessive accelerator concentrations or incompatible formulations may produce uneven or excessively tight cross-links, which can increase internal stress and accelerate property degradation over time. Therefore, selecting the appropriate type and dosage of accelerator is crucial for maintaining long-term aging resistance.

Impact on Ozone Resistance

Ozone exposure can cause surface cracking and mechanical failure in rubber materials, particularly in elastomers with high unsaturation levels. The effect of Rubber Accelerator on ozone resistance depends on its influence on the molecular structure and cross-link distribution. Accelerators that facilitate a stable, well-distributed network can improve resistance to ozone-induced cracking by reducing the mobility of polymer chains at the surface. Additionally, combining accelerators with anti-ozonants or protective additives can further enhance durability. Improper formulation, however, may create localized stress points that increase vulnerability to ozone attack.

Interplay with Other Additives

The performance of rubber accelerators regarding aging and ozone resistance is closely linked to their interaction with other compounding ingredients. Fillers, stabilizers, and anti-degradants can synergistically improve resistance when properly combined with the accelerator. For instance, sulfur-based accelerators often work effectively with antioxidants to delay oxidative aging, while certain combinations with reinforcing fillers can enhance resistance to mechanical and ozone-induced surface stress. Understanding these interactions allows manufacturers to formulate rubber compounds that balance curing efficiency with long-term durability.

Practical Recommendations for Durable Rubber Compounds

To improve both curing performance and resistance to aging and ozone, several practices should be considered. Selecting accelerators compatible with the base rubber and other additives ensures uniform cross-linking. Second, adhering to recommended dosage levels prevents over-curing or uneven network formation. Third, incorporating appropriate stabilizers and antioxidants complements the accelerator’s function, enhancing long-term durability. Finally, monitoring processing conditions, such as temperature and curing time, helps maintain the integrity of the rubber network and prevents premature degradation.

Optimizing Rubber Accelerator Use for Longevity

Rubber Accelerator can influence the aging and ozone resistance of vulcanized rubber by affecting cross-link density, network uniformity, and interactions with other additives. Proper selection, dosage, and formulation design are essential to ensure that the accelerator improves curing efficiency without compromising long-term durability. By considering these factors, manufacturers can produce rubber products that retain mechanical strength, elasticity, and surface integrity over time, even under environmental stressors such as heat, oxygen, and ozone exposure. Effective accelerator management ultimately contributes to more reliable, longer-lasting rubber components suitable for demanding industrial and consumer applications.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体