Custom Cheap Chemical Cold Car Tire Vulcanizing Fluid in China

The rubber industry is a dynamic sector that has been significantly influenced by the process of chemical vulcanizing. This method, which involves the use of chemicals to improve the physical properties of rubber, has been a key factor in the evolution of rubber processing. As the industry moves forward, the role of it in shaping the future of rubber processing becomes increasingly evident. This article will discuss the impact of Custom chemical vulcanizing on the rubber industry, its applications, and how it is poised to influence future developments.

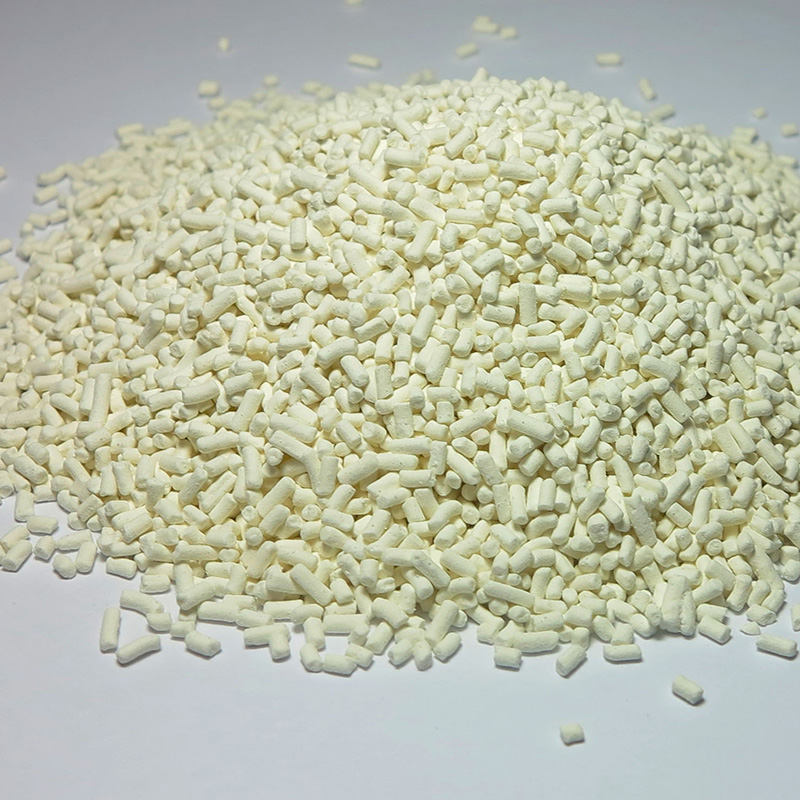

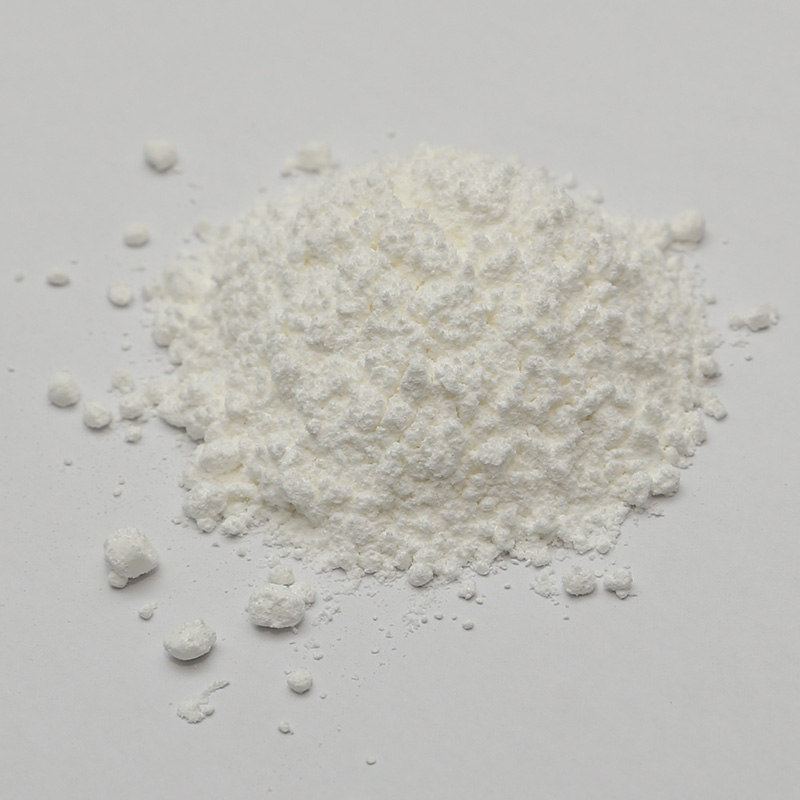

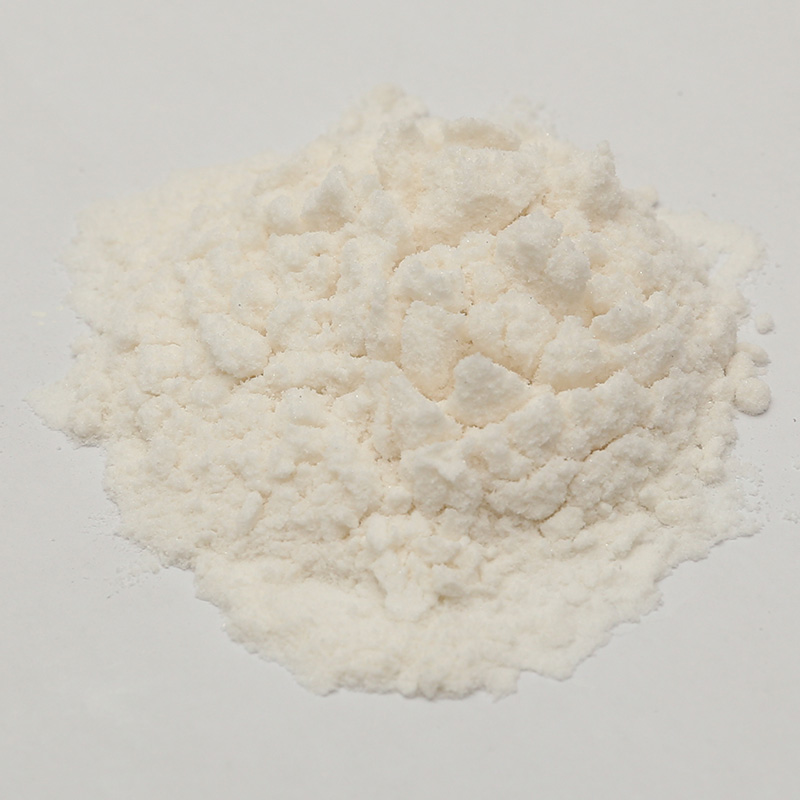

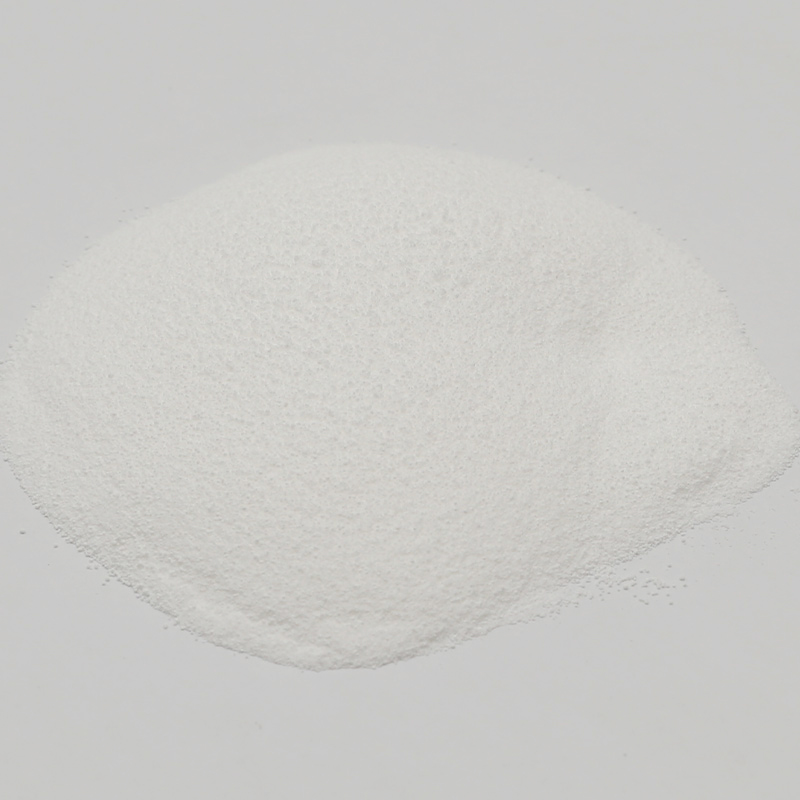

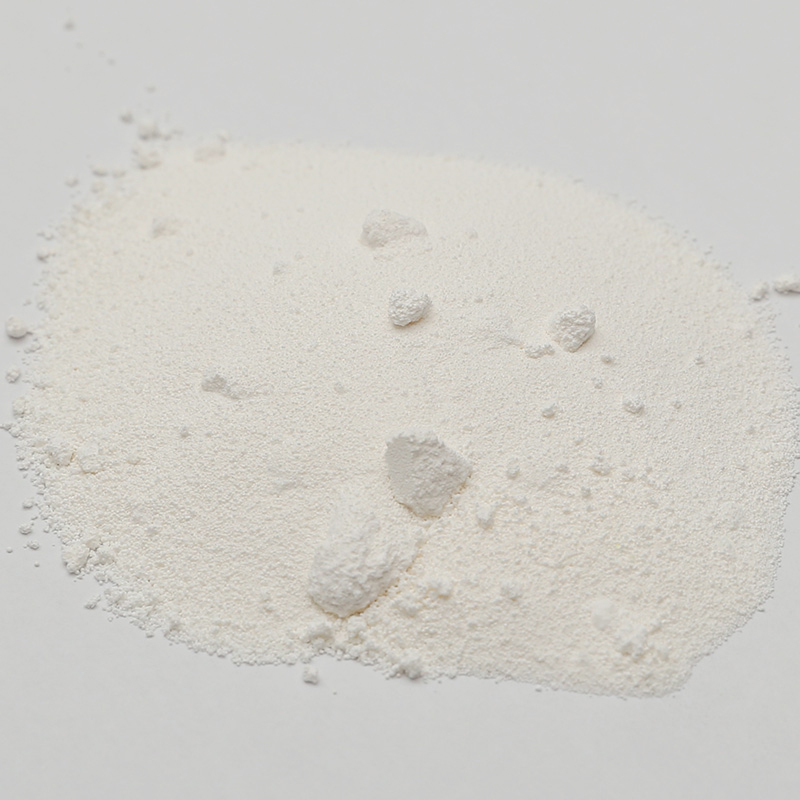

Chemical vulcanizing is a process that has been integral to the rubber industry since its inception. It involves the use of specific chemicals, known as vulcanizing agents, to induce cross-linking between polymer chains in rubber. This cross-linking results in improved strength, elasticity, and resistance to heat and chemicals. The process is essential for creating rubber products that can withstand the rigors of various applications, from tires to seals and gaskets.

The history of rubber processing is closely tied to the development of chemical vulcanizing. Before the discovery of vulcanization, rubber was prone to melting in hot temperatures and becoming brittle in cold ones. The invention of it by Charles Goodyear in the 19th century was a breakthrough that allowed rubber to become a versatile material suitable for a wide range of uses. Since then, chemical vulcanizing has been refined and adapted to meet the evolving needs of the rubber industry.

Today, chemical vulcanizing is used in a variety of applications across different industries. In the automotive sector, it is crucial for the production of tires that can handle high speeds and various weather conditions. In the construction industry, it ensures the durability of rubber seals and waterproofing materials. Additionally, in the manufacturing of hoses and belts, it provides the necessary resilience and flexibility.

The rubber industry is constantly seeking ways to improve the efficiency and sustainability of chemical vulcanizing. Recent innovations have focused on developing more environmentally friendly vulcanizing agents and processes. These efforts aim to reduce the environmental impact of rubber production while maintaining the high standards of product quality that chemical vulcanizing provides.

Sustainability has become a critical concern in the rubber industry, and Cheap Cold Vulcanizing Fluid plays a significant role in addressing this issue. By optimizing it process, manufacturers can reduce waste and energy consumption, resulting in more sustainable rubber products. Research is ongoing to find alternative vulcanizing agents that are less harmful to the environment while still providing the necessary properties of rubber.

As the rubber industry continues to grow, the demand for advanced chemical vulcanizing techniques will also increase. The future of rubber processing is likely to involve more precise control over the vulcanizing process, allowing for the creation of rubber products with tailored properties. This could result in the development of new materials with improved performance characteristics, such as higher strength, better heat resistance, and longer lifespans.

To ensure the continued success of the rubber industry, it is essential to invest in education and training related to chemical vulcanizing. By equipping the next generation of rubber technologists with a deep understanding of it, the industry can continue to innovate and meet the challenges of the future.

Car Tire Vulcanizing in China has been and will continue to be, a pivotal process in the rubber industry. Its ability to enhance the properties of rubber has made it an indispensable part of rubber processing. As the industry moves forward, the focus on innovation, sustainability, and education will be crucial in shaping the future of chemical vulcanizing. By embracing these challenges, the rubber industry can continue to thrive and provide the high-quality products that are essential to our modern world.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体