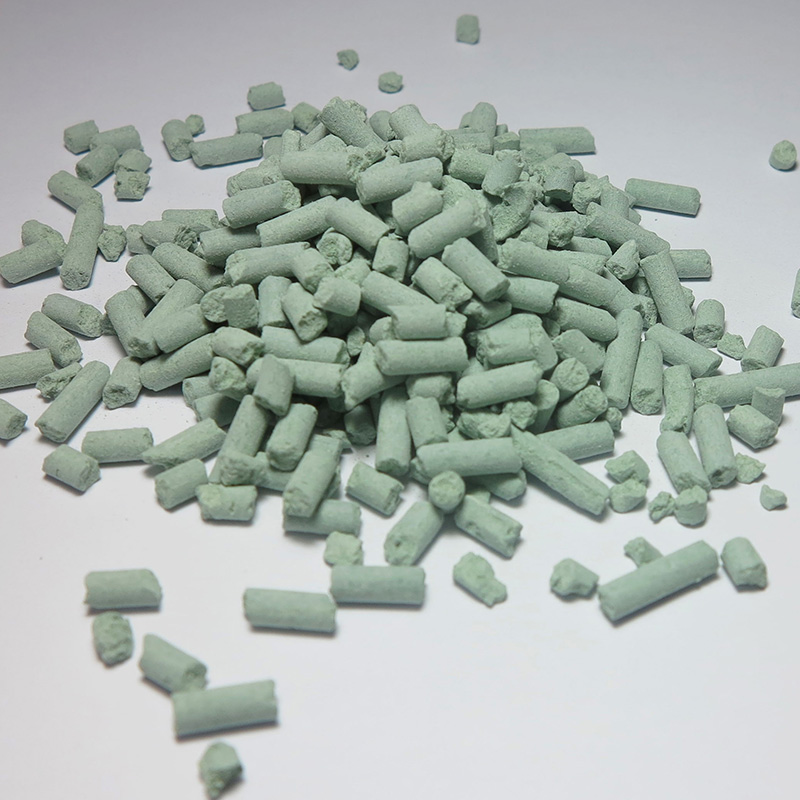

China Custom Antioxidant Stop Oxidation Prevention Agent Supplier

Antioxidant agents are essential compounds widely used in industrial applications to enhance the stability and longevity of materials. These agents play a crucial role in protecting products from oxidative degradation, which can result in reduced performance, strength, and durability. Oxidation is a common issue that affects various materials, particularly in industries like rubber, plastics, food packaging, and coatings. In this article, we will explore the different types of China antioxidant agents used in industrial applications, focusing on their functions and benefits.

An antioxidant agent is a substance that helps prevent or delay the oxidation process by neutralizing free radicals. Free radicals are reactive molecules that can cause damage to a material by attacking its molecular structure. This process results in the degradation of the material, weakening its properties. By incorporating it, industries can slow down this process and protect products from premature failure.

There are two main categories of antioxidant agents: primary and secondary antioxidants. Primary antioxidants are commonly used in industrial applications. These agents work by directly scavenging free radicals, effectively preventing the initiation of the oxidation chain reaction. They are usually reactive compounds that donate electrons to free radicals, neutralizing their reactivity. Primary antioxidants are widely used in the manufacturing of rubber, plastics, and lubricants to extend the lifespan of these materials.

Secondary antioxidants, on the other hand, do not directly neutralize free radicals but instead work by stabilizing other oxidative intermediates, such as peroxides, that contribute to the degradation process. These agents can decompose peroxides before they can cause significant damage to the material. Secondary antioxidants are often used in combination with primary antioxidants to offer more comprehensive protection against oxidation in industrial products.

In the rubber industry, Custom Aluminum Oxidation Preventions are used to improve the stability of tires and other rubber products. Rubber is prone to oxidative degradation, especially when exposed to heat, ozone, and UV radiation. Primary antioxidants like amines and phenols are often used to prevent the breakdown of rubber, thereby enhancing its durability and performance. Secondary antioxidants, such as phosphites and thioesters, are frequently added to further protect rubber from oxidative damage.

In the plastics industry, antioxidant agents are used to stabilize polymer materials and maintain their mechanical properties during processing and throughout their life cycle. Polymers, such as polyethylene and polypropylene, are highly susceptible to oxidation when exposed to heat and oxygen during production. Antioxidant agents, including hindered amine light stabilizers (HALS) and phenolic compounds, help to prevent oxidative degradation in these materials, allowing them to retain their strength and flexibility.

Food packaging is another area where antioxidant agents are essential. Packaging materials, such as films and containers, are exposed to oxygen, which can result in the degradation of food products. They are incorporated into packaging materials to prevent the oxidation of food, preserving its freshness and extending its shelf life. Common ones in food packaging include ascorbic acid and tocopherols, which help to inhibit the formation of free radicals and protect food from spoilage.

Coatings and paints also benefit from the inclusion of antioxidant agents. These materials are exposed to environmental factors like moisture, UV radiation, and oxygen, which can cause degradation over time. Stop Oxidation Suppliers, including hindered phenols and phosphates, are added to coatings and paints to prevent discoloration, cracking, and loss of adhesion, ensuring that the coatings retain their aesthetic and functional properties for a longer period.

In conclusion, antioxidant agents are vital components in many industrial applications, providing protection against oxidation and extending the lifespan of materials. Primary antioxidants, secondary antioxidants, and a combination of both offer varying levels of protection depending on the material and application. From rubber and plastics to food packaging and coatings, they contribute significantly to the performance, safety, and sustainability of industrial products. As industries continue to seek more durable and long-lasting materials, the role of antioxidant agents will remain essential in meeting these demands.

English

English Português

Português Español

Español русский

русский 中文简体

中文简体